Ukuthanjiswa kwezixhobo zokuqhuba ezivulekileyo ezisetyenziswa kwimizi-mveliso eyahlukeneyo enje ngesamente kunye nezixhobo zamalahle, iziko elijikelezayo, okanye apho iimeko zokutywinwa zinzima, iigrisi ezinolwelo olunesiqingatha zihlala zisetyenziswa ngokukhetha ioyile yolwelo. Ukusetyenziswa kwegirth gears zisetyenziswa kunye ne-splash okanye inkqubo yokutshiza yokuthambisa. Ukukhethwa kwamafutha anjalo kuchaphazela ixesha lokuphila kunye nomthwalo wokuthwala umthwalo weegiya, kunye nokuziphatha okunxitywayo.

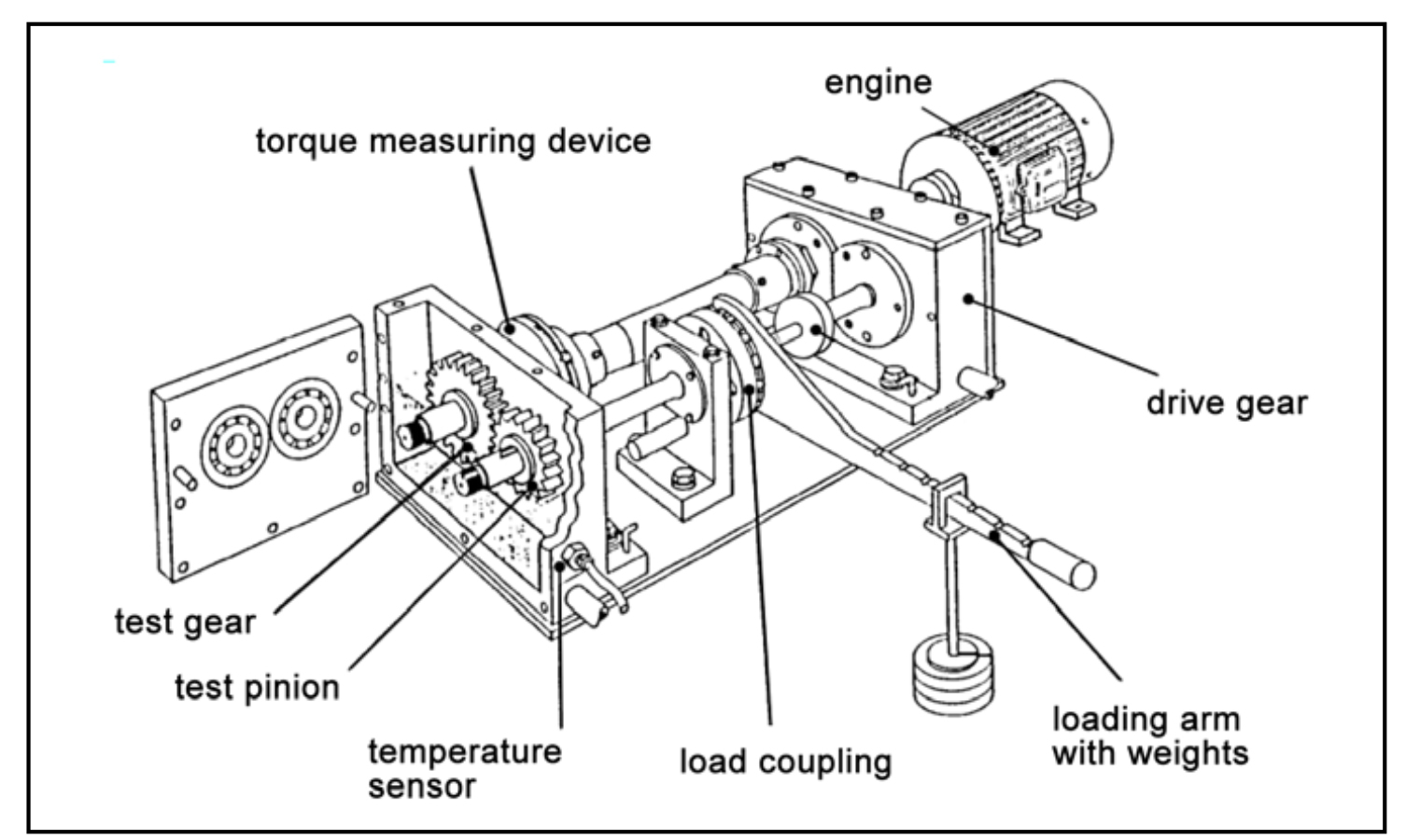

Uphando luye lwenziwa uthelekiso phakathi kwe-oyile ye-fluid kunye ne-semi-fluid eyahlukeneyo (NLGI00) yegrease formulations, eyahlukileyo ngokumalunga ne-viscosity ye-oyile esisiseko, uhlobo lwe-thickener kunye nokongezwa kwezizongezo zolwelo kunye neziqinileyo. Uvavanyo lokuqhuba ukumiselwa kweeparamitha ezahlukeneyo zenziwa kwiirigi zokuvavanya iigiya ezibuya ngasemva; ukuseta isicwangciso sovavanyo siboniswa apha ngezantsi.

Iziphumo zovavanyo zibonisa ukuba iigrisi zegiya ze-NLGI 00 ezihambelanayo zibonisa phantse ubomi obufanayo bokugoba njengabalingane babo beoyile. Ngaphaya koko, i-kinematic viscosity ye-oyile yesiseko ibonisa impembelelo enkulu kwi-pitting lifetime of such NLGI 00 grade greases. Ukongezwa kwegraphite ekhethekileyo yokwenziwa kwigrisi enjalo yakhokelela ekunciphiseni ubomi bomgodi kunye nokunxiba okuphezulu. Iziphumo zovavanyo zikwabonisa ukuba umthamo we-pitting load of the greases uhambelana ne-kinematic viscosity ye-oyile yesiseko. Ukusebenzisa isiseko esiphezulu se-oyile viscosity, ixesha elide lokubeka i-oyile kunye nomthamo wokuthwala umthwalo ophezulu wokugoba uye waphunyezwa. Ukufumana igrisi ye-semi-fluid gear, ukubalwa komthwalo wokuthwala umthwalo ngokwe-ISO 6336 kusetyenziswa i-viscosity yesiseko yeoli ihambelana kakuhle neziphumo zovavanyo olusebenzayo. Iimvavanyo zokuhlalutya ukuziphatha okunxibayo kwegrisi ezahlukeneyo ze-semi-fluid zenziwa kuvavanyo lokunxiba A/2.8/50 ngokwesiseko se-ISO 14635-3 kunye ne-ISO 14635-1. Iindidi ezine zokugqoka ezihlukeneyo zichazwe kuvavanyo lokunyamezela iiyure ezili-100 kunye nokuhlelwa okwenziwe ngokwexabiso lokugqoka kwi-pinion kunye nevili. Ngokuqhelekileyo, phantse zonke izithambiso eziphandiweyo, ngaphandle kwamafutha aqulethe izithambiso eziqinileyo, zibonisa ukuguga okuphantsi kuwo onke amalungu ovavanyo. Impembelelo ye-viscosity ye-oyile esisiseko inokubonwa kwinto yokuba igrisi ezine-viscosity ephezulu ye-oyile zibonisa ukunxiba okuphantsi. Iimpembelelo zokuxinana kwe-thickener kunye nohlobo lwe-thickener luphantse lungabinamsebenzi, kodwa igrisi enesepha ye-aluminiyam entsonkothileyo ibonisa nje isixa esincinci sokunxiba esiphezulu xa kuthelekiswa ne-lithium-thicken counter part. Umahluko obaluleke kakhulu unokubonwa kwimpembelelo yesixa kunye nohlobo lwesithambiso esiqinileyo. Amafutha aqulethe igraphite yokwenziwa abonisa iimali zokunxiba eziphezulu kakhulu - ezinxibelelana nesixa segraphite kwigrisi - xa kuthelekiswa negrisi efanayo engenazithambiso eziqinileyo. Ekupheleni kovavanyo lwenyathelo igrisi equlathe i-4.2% yegraphite ibonisa ukunxiba okuphindwe kathathu ngaphezulu kwegrisi yesiseko. Kwaye kunye nomlinganiselo ophezulu we-graphite - i-11.1% -ixabiso lokunxiba liye lanyuka ukuya kwinqanaba eliphindwe kasibhozo xa kuthelekiswa negrisi engenazo izinto eziqinileyo. Olu tyekelo lwaqinisekiswa nakuvavanyo lonyamezelo; oko kukuthi - i-graphite eninzi, iphezulu yokunxiba. Kwelinye icala, igrisi equlethe i-4.2% ye-molybdenum disulphide ibonisa ukunxitywa okufanayo. Xa i-spur gearset iqala ukujikeleza, igrisi esecaleni kwesixhobo iyalahlwa ngoko nangoko kwaye ayibuyeli kweso sixhobo ngenxa yokunqongophala kwesixhobo sokuphinda sigcwalise. Kwenziwa umsantsa phakathi kweegiya ezijikelezayo kunye nentlaka yegrisi. Akukho grisi amatsha impompozayo ukusuka kwisump ukuya kwisixhobo segiya ngenxa yokungaguquguquki kwayo okuqinileyo. Ukunqongophala kokuthambisa kunye nokupholisa kunokubonwa okunokukhokelela kumaqondo obushushu obuninzi kwiigiya kwaye, ekugqibeleni, ukubetha. Kuphela inani elincinci legrisi elithatha inxaxheba kwi-lubrication. I-Channeling iyenzeka ikakhulu kuma-40 kunye nama-50% amanqanaba okuzalisa kunye ne-stiffer prod ukuya kwigrisi yesiseko emva kovavanyo lwamanyathelo kunye nokunxiba okungaphezulu kancinci emva kovavanyo lonyamezelo.

Kwimeko eyahlukileyo, ekuthanjisweni kwezixhobo ezincinci, ezivaliweyo zegiya ezisetyenziswa kwizixhobo zombane okanye kwizicelo zonyango, kunye nokuthambisa iibhokisi zegiya ezincinci kwiimeko ezinzima zokutywinwa, kukhethwa iigrisi ezomeleleyo, rhoqo ze-NLGI 1 okanye 2 ukungaguquguquki. . Ukukhethwa kohlobo lwegrisi kunye nenqanaba lokuzalisa lichaphazela ukusebenza kakuhle, umthamo wokuthwala umthwalo kunye nokuhanjiswa kobushushu kwibhokisi yegiya.

Ixesha lokuposa: Aug-10-2021