SDNL550 SDNL600 SDNL650 SDNL700 SDNL750 SDNL800 SDNL850 SDNL900 SDNL950 SDNL1000 SDNL1050 SDNL1100 SDNL1150SDNL1120

SDVL550 SDVL600 SDVL650 SDVL700 SDVL750 SDVL800 SDVL850 SDVL900 SDVL950 SDVL1000 SDVL1050 SDVL1100 SDVL1150 SDVL1150 SDVL1150 SDVL

SVNL550 SVNL600 SVNL650 SVNL700 SVNL750 SVNL800 SVNL850 SVNL900 SVNL950 SVNL1000 SVNL1050 SVNL1100 SVNL1150 SVNL

SVVL550 SVVL600 SVVL650 SVVL700 SVVL750 SVVL800 SVVL850 SVVL900 SVVL950 SVVL1000 SVVL1050 SVVL1100 SVVL1150 SVVL1150

SFNL550 SFNL600 SFNL650 SFNL700 SFNL750 SFNL800 SFNL850 SFNL900 SFNL950 SFNL1000 SFNL1050 SFNL1100 SFNL11500

SFVL550 SFVL600 SFVL650 SFVL700 SFVL750 SFVL800 SFVL850 SFVL900 SFVL950 SFVL1000 SFVL1050 SFVL1100 SFVL1150 SFVL11500

Umlinganiselo: 18 20 22.4 25 28 31.5 35.5 40 45 50 56 63 71 80 90 100 112 125 140 160 180 200 224 250 28005 31 710 800

Iiyunithi zegiya ziphawulwa ngenqanaba lengxolo ephantsi, ephunyezwa ngamagiya e-helical ngoqhagamshelwano oluphezulu.

umlinganiselo kunye nezindlu ezidambisa isandi¬.

Iimpawu ezintle zobushushu beyunithi yegiya zifezekiswa ngomgangatho ophezulu wokusebenza kakuhle, omkhulu

umphezulu wendlu kunye nenkqubo yokupholisa enxulumene nokusebenza.

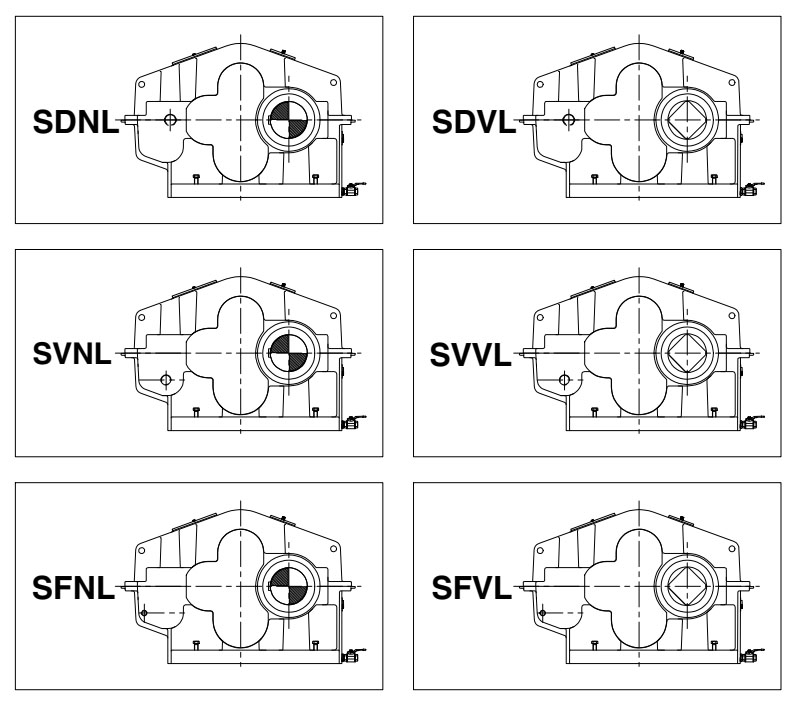

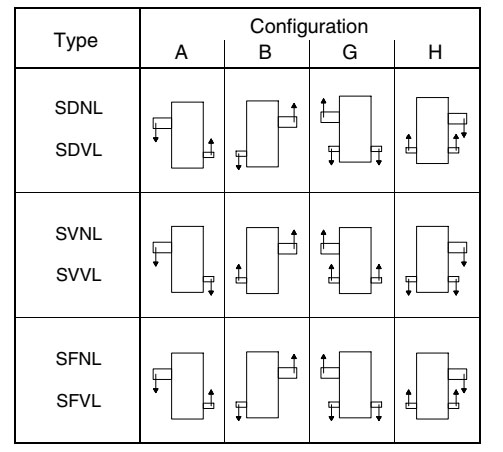

Inani lokucwangciswa kwe-shaft (iintlobo kunye nezikhokelo zokujikeleza) zinokwenzeka. Ezi ziboniswe kwi

Itheyibhile elandelayo njengeeshafu eziqinileyo: Iintolo ezinecala lokujikeleza zibonisa unxulumano phakathi kwe

izalathiso zokujikeleza kwegalelo kunye neeshafti zemveliso.

Amazinyo e-helical¬gear aqinisiwe kwaye aphantsi. Umgangatho ophezulu wamazinyo ukhokelela kwinto ebalulekileyo

ukunciphisa ingxolo kwaye iqinisekisa ukubaleka okukhuselekileyo nokuthembekileyo.

Ukwabelana ngomthwalo kuqinisekisa ukuba amandla egalelo aziswayo abiwe phakathi kwemigca emibini kwaye adluliselwe kuyo

igiya yeshaft yokuphuma ngeentsiba zayo zombini imigca. Oku kubangela ukusetyenziswa kabini kwegiya enkulu ye

inqanaba lemveliso kwaye ivumela uyilo lwayo usebenzisa imilinganiselo emincinci.

Iigiya zidityaniswe neeshafti ngokungenelela kokuphazamiseka kunye nezitshixo ezinxuseneyo okanye ngokucutha ukulingana. Ezi ntlobo

Amalungu ahambisa ngokuthembeka okwaneleyo iitorque ezenziweyo.

Ukuthanjiswa kwazo zonke iindawo ezilungiselelweyo kunye neebheringi zenziwa ngokuchaphaza okudityanisiweyo kunye nokunyanzeliswa kokuthambisa.

ngempompo eqhutywa yinjini.

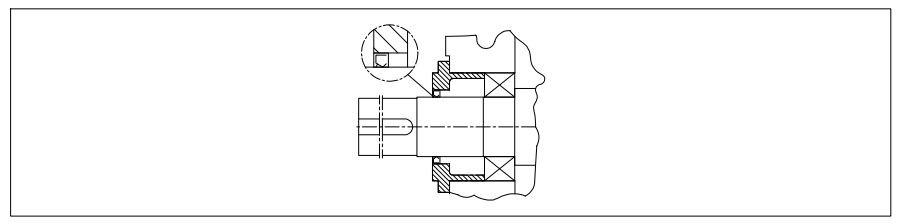

Ngokuxhomekeke kwiimfuno, iiringi zokutywina ze-radial shaft¬, okanye iTaconite okanye iTacolab etywiniweyo ixhonywe kwindawo.

indawo yokuphuma ukuthintela i-oyile ukuba ingavuzi kwindlu kunye nokungcola ekungeneni kuyo.

Izangqa ze-radial shaft¬ zokutywina

Iiringi zokutywina ze-radial luhlobo olusemgangathweni lwetywina. Zifakwe ngokufanelekileyo ngothuli olongezelelweyo

umlebe ukukhusela umlebe otywiniweyo wokwenene ekungcoleni kwangaphandle.

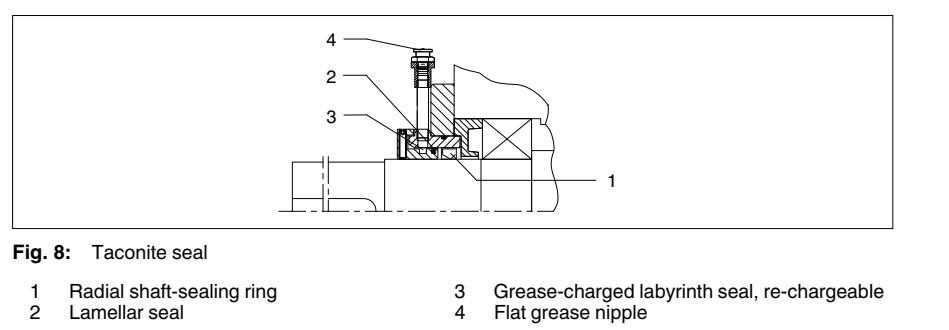

Itywina leTaconite

Amatywina eTaconite aphuhliswe ngokukodwa ukuba asetyenziswe kwindawo enothuli. Ukungena kothuli

ithintelwe yindibaniselwano yezinto ezintathu zokutywina (i-radial shaft¬sealing ring, i-lamellar seal kunye

ilabyrinth seal etshajiweyo etshajiweyo kwakhona)

Tacolab itywina

Izitywina zeTacolab azidibanisi, zisebenza ngokukhululekileyo kwaye zifuna ukulungiswa okuncinci kwaye

nto leyo eqinisekisa iimpawu ezifanelekileyo zobushushu. Zingasetyenziswa kuphela ngokunyanzeliswa okongeziweyo

ukuthambisa zonke iibheringi kunye nenqanaba le-oyile elincitshisiweyo.

Itywina leTacolab lenziwe ngamalungu amabini:

─ i-labyrinth yeoli ekhusela ioli yokuthambisa ukuba ingaphumi

─ isitywina sothuli esigcwele igrisi, esivumela ukusetyenziswa kwiindawo ezinothuli kakhulu.