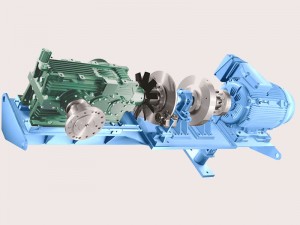

vibration excitor gearbox gear unit HE150S HE180S

Sizes:

HE100S HE120S HE150S HE180S HE200S

• Oil pressure lubrication with flanged-on pump

• Reinforced bearings

• Dry well design (shaft seal is absolutely oil-tight)

• Vibrator excitor arm included

• High operational reliability

• Low noise level

• High efficiencies

Gearbox with Smith Stone machine available for excitor gearbox, special design for long life with low carbon alloy with caburizing and quenching to HRC58-62, grounded to DIN grade 6 for low noise.

With excited clamp for easy fixing double arm in machine.

Applications

• Vibration excitor

Taconite seal

The taconite seal is a combination of two sealing elements:

• Rotary shaft sealing ring to prevent the escape of lubricating oil

• Grease-filled dust seal (comprising a labyrinth and a lamellar seal) to allow operation of the

gear unit in extremely dusty environments

The taconite seal is ideal for use in dusty environments

Oil level monitoring system

Depending on the order specification, the gear unit can be equipped with an oil level monitoring system based on a level monitor, a level switch or a filling-level limit switch. The oil level monitoring system has been designed to check the oil level when the gear unit is at a standstill before it starts.

Axial load monitoring

Depending on the order specification, the gear unit can be equipped with an axial load monitoring system. The axial load from the worm shaft is monitored by a built-in load cell. Connect this to an evaluation unit provided by the customer.

Bearing monitoring (vibration monitoring)

Depending on the order specification, the gear unit can be equipped with vibration sensors,

sensors or with threads for connecting equipment for monitoring the rolling-contact bearings or gearing. You will find information about the bearing monitoring system design in the separate data sheet in the complete documentation for the gear unit.

As an alternative, measuring nipples can be attached to the gear unit to prepare it for monitoring