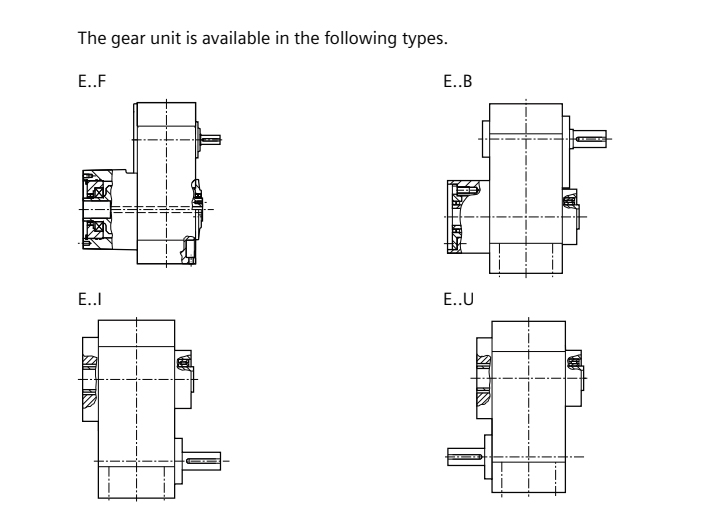

Li-gear tsa li-screw extruder tse le 'ngoe

Boholo:

E2U E3U E4U E5U E6U E7U E8U E9U E10U E11U E12U

E2F E3F E4F E5F E6F E7F E8F E9F E10F E11F E12F

E2I E3I E4I E5I E6I E7I E8I E9I E10I E11I E12I

E2B E3B E4B E5B E6B E7B E8B E9B E10B E11B E12B

Moqapi o tiileng

Ho ntša lerata le tlaase

Matla a phahameng ka ho fetisisa a axial a khoneha ka lebaka la li-thrust bearings tse kentsoeng ka pel'a mochine oa lisebelisoa

Ts'epehiso e phahameng ka ho fetisisa ea ts'ebetso ka lebaka la ho sutumetsa ka phaposing ea oli ea yuniti ea gear

Nako e fokotsehileng ea ho fana

SKLE SCREW – TŠOANTŠISO TSE MANGATA

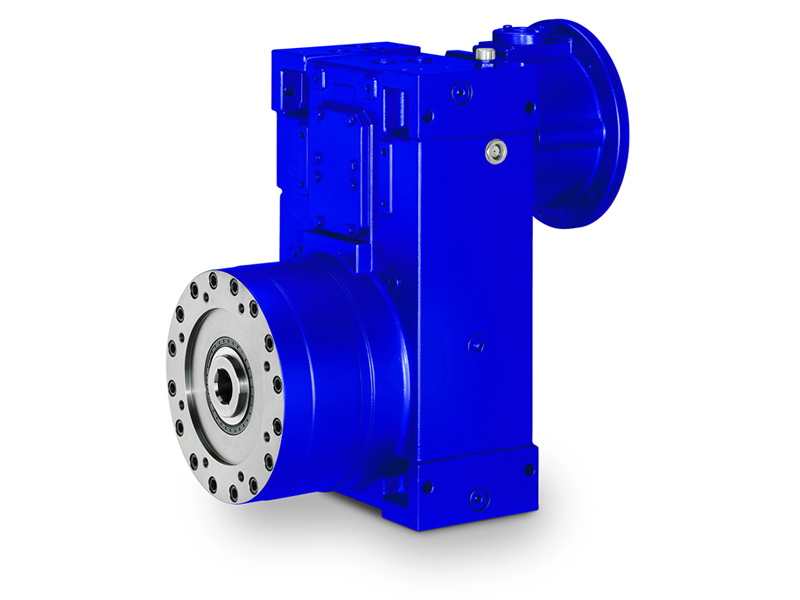

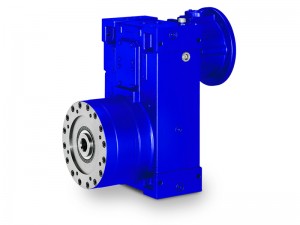

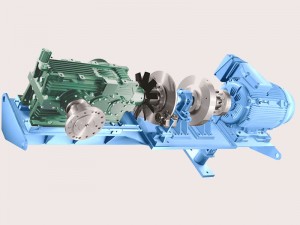

Ha ho etsoa rabara le lipolasetiki, mefuta e mengata e fapaneng ea thepa e hloka ho nepahala ho phahameng haholo ha mechini e sebetsang. Ke ka nako eo feela litebello tse phahameng tsa bareki mabapi le sehlahisoa sa ho qetela li ka finyelloang. Matla a phahameng a axial a tsoang ts'ebetsong ea extrusion a tlameha ho kenngoa. Li-gear tsa rona tsa "screw extruder" li sebelisoa haholo limela bakeng sa ho etsa polasetiki, 'me li khetholloa ka ts'epo e phahameng ea ts'ebetso le linako tse khutšoane tsa ho fana. Letoto le tloaelehileng le na le likarolo tsa 2- le 3-helical kapa worm gear tse nang le li-thrust bearings kapa li-thrust bearings tse kentsoeng ka pel'a yuniti ea gear. Li-torque tse tsoang ho 6,300 ho isa ho 173,000 Nm lia khoneha.

Lisebelisoa

Mefuta e mengata ea lisebelisoa, mohlala, bakeng sa:

Rabara bakeng sa mabanta a conveyor

Lithaere tsa koloi

Filimi/mashiti a polasetiki, mohlala, filimi ea ho paka, mekotlana e tsamaisang thepa, masela a mapolanka bakeng sa masimo.

Filimi ea lijo, mekotla ea polokelo ea lijo

Sephutheloana (Tetra-Pak)

Liboto tsa ho futhumatsa mocheso (polystyrene)

Li-rotor blades bakeng sa li-turbine tsa moea

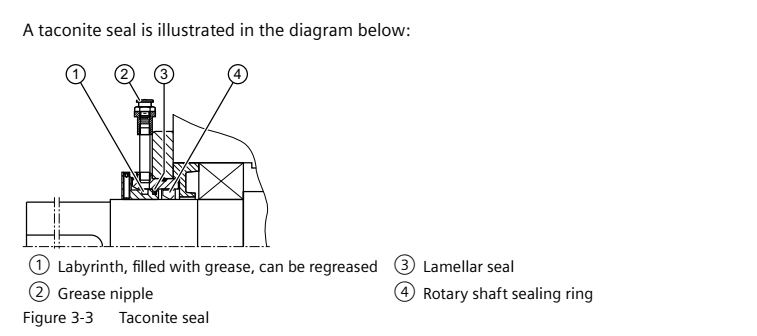

Tiiso ea Taconite

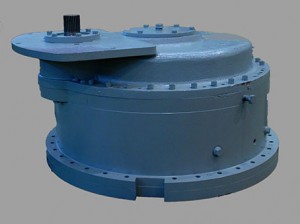

Setiiso sa taconite ke motsoako oa likarolo tse peli tsa ho tiisa:

• Rotary shaft ho tiisa lesale ho thibela ho tsoa ha oli e tlotsang

• Setiiso sa lerole se tlatsitsoeng ka mafura (se nang le labyrinth le lamellar seal) ho lumella tšebetso ea

yuniti ea lisebelisoa libakeng tse lerōle haholo

Setiiso sa taconite se loketse ho sebelisoa libakeng tse lerōle

Mokhoa oa ho shebella boemo ba oli

Ho ipapisitsoe le tlhahiso ea taelo, yuniti ea gear e ka hlomelloa ka sistimi ea ho shebella boemo ba oli e thehiloeng ho sebali sa boemo, switch ea boemo kapa switch ea moeli oa ho tlatsa. Sistimi ea ho lekola boemo ba oli e etselitsoe ho lekola boemo ba oli ha yuniti ea gear e eme pele e qala.

Axial load monitoring

Ho itšetlehile ka tlhaloso ea taelo, yuniti ea gear e ka hlomelloa ka tsamaiso ea axial load monitoring system. Moroalo oa axial o tsoang sebokong sa seboko o hlahlojoa ke sele ea mojaro e hahiloeng. Hokela sena ho karolo ea tlhahlobo e fanoeng ke moreki.

Ho beha leihlo (ho beha leihlo ho thothomela)

Ho ipapisitse le litlhaloso tsa odara, yuniti ea gear e ka ba le li-sensor tsa vibration,

li-sensor kapa tse nang le likhoele bakeng sa lisebelisoa tse hokahanyang bakeng sa ho lekola li-bearings kapa li-gearing. U tla fumana leseli mabapi le moralo oa sistimi ea ho beha leihlo pampiring e arohaneng ea data litokomaneng tse felletseng tsa yuniti ea lisebelisoa.

E le mokhoa o mong, li-nipples tsa ho lekanya li ka kopanngoa le lihlopha tsa lisebelisoa.