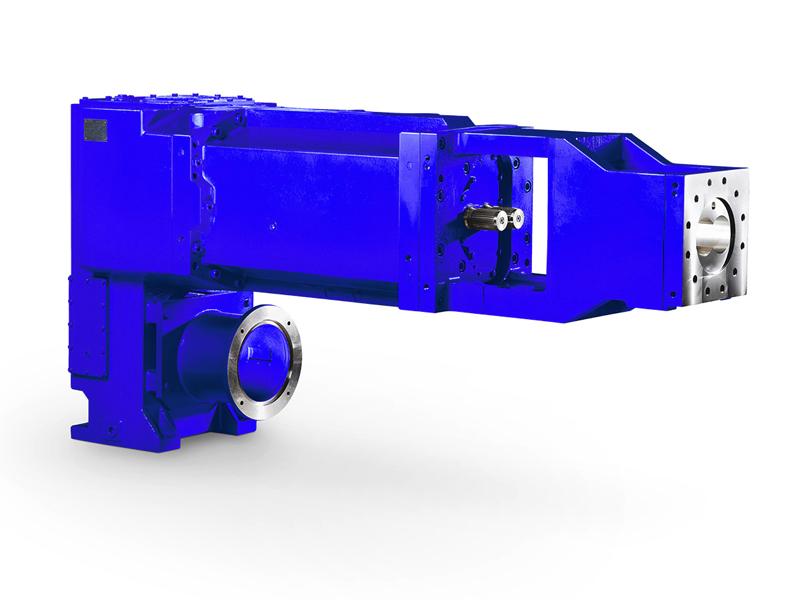

li-gear tse peli tsa screw extruder

Boholo:

61 G5070, 73 G 9000, 93 G 17850, 108G 28100, TG3. Boholo ba 50 ho isa ho 750

73 F ho isa ho 133 F boholo 7500 ho 45000

Setsi sa gear se nang le ts'ebetso e phahameng ea matla

Linako tse khutšoane tsa ho fana ka thepa ka lebaka la maemo a tsitsitseng a matlo le likarolo tsa kahare

Liphetoho tsa sebaka sa bohareng li ka etsoa kapele le ka boiteko bo fokolang ba boenjiniere le litšenyehelo.

Helical gear units for double-screw extruder tse nang le parallel drive shafts le tsela e ts'oanang ea screw rotation li fumaneha ka boholo bo fapaneng sebakeng sa ts'ebetso lipakeng tsa 200 le 35 000 Nm ka shaft le ho fihla ho 20 000 kW. Li sebelisoa haholo-holo ha ho etsoa li-granulate le ho hloekisoa ha lipolasetiki tse tala hammoho le indastering ea pente le ea lacquer le liindastering tsa ho hlatsoa, lijo le liindasteri tsa phepelo ea liphoofolo.

Lisebelisoa tsa lisebelisoa tsa Extruder ke tsona tse khannang ka ho fetisisa maemong 'ohle, hobane li sebetsa hantle ebile li ka tšeptjoa. Ka lebaka la bophelo ba bona bo bolelele ba tšebeletso le tlhoko ea bona ea mosebetsi o fokolang oa tlhokomelo, ba emela tharollo e ntle moruong lefatšeng ka bophara.

Likarolo tsa lisebelisoa tsa Helical bakeng sa li-extruder tse nang le li-screw tse peli le tsona li maemong a holimo haholo 'me li lumella tlhophiso e ikhethileng ea bareki ntle le bothata. Mohlala, litokiso tsa sebaka se bohareng li ka etsoa ka boikitlaetso bo fokolang haholo le litšenyehelo tse nyane, ka hona, ho nolofalletsa mefuta e fapaneng e ikhethileng ea bareki.

Extruder e entsoeng ka makhetlo a mabeli (ea synchronous)

E le hore re khone ho monya li-torque tse phahameng haholo le matla a axial a thehiloeng ke mokhoa oa extrusion, re thehile yuniti ea lisebelisoa tsa extruder tse nang le tsamaiso e habeli ea ho arola matla le li-bearings tse khethehileng. Sistimi ea ho jara e ka ba le li-thrust bearings tse fihlang ho tse robeli tse behiloeng ka morao ho tse ling. Li-torque tse tsoang ho 200 ho isa ho 35,000 Nm le libaka tse bohareng tse pakeng tsa 18.3 le 140 mm li ka phethahala. Ho feta moo re ka fana ka litharollo tse entsoeng ke bareki tse fihlang ho 20,000 kW.

Lisebelisoa

Likarolo tsa lisebelisoa tsa Helical bakeng sa li-extruder tse nang le li-screw tse peli tse nang le li-shafts tse tšoanang tsa ho potoloha ka tsela e ts'oanang li sebelisoa haholo ha ho etsoa li-granulate le ho hloekisoa ha polasetiki e tala. Libaka tse ling tsa kopo li kenyelletsa:

Indasteri ea pente le lacquer

Indasteri ea ho hlatsoa liaparo

Indasteri ea lijo (mohlala, bohobe, pasta)

Indasteri ea phepelo ea liphoofolo (ntja, katse lijo tsa liphoofolo tse ling)

Mochini oa li-screw tse peli (contra-rotatory)

Lefapheng la extrusion, hammoho le li-gear tsa co-rotatory double-screw extruder gear, re boetse re fana ka li-unit tsa li-extruder tsa "contra-rotatory double-screw extruder" ka liphetolelo tse otlolohileng le tse rapameng. Libaka tse pakeng tsa 60 le 140 mm le li-torque tse pakeng tsa 5,000 le 60,000 Nm li ka phethahala.

Lisebelisoa

Liphaephe (lipeipi tsa metsi a litšila, lipeipi tsa fatše, lipeipi tsa moea)

Profiles

Liforeimi tsa lifensetere

Sidings

Li-foils

Lintho tsa ho paka

Liboto tse thibelang mocheso

Li-rotor blades bakeng sa li-turbine tsa moea

Lithaere

Mehala ea kopano

Mabanta a conveyor

Lisebelisoa tsa indasteri ea likoloi

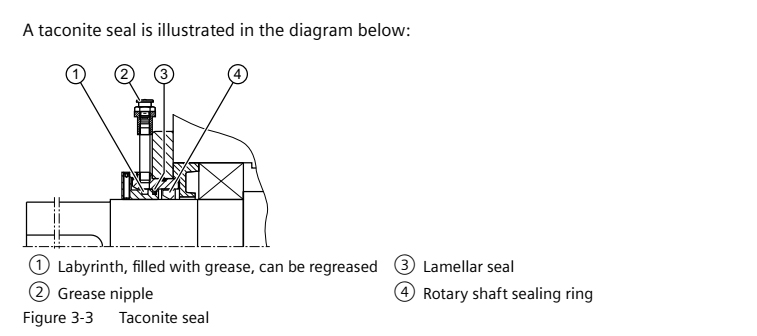

Tiiso ea Taconite

Setiiso sa taconite ke motsoako oa likarolo tse peli tsa ho tiisa:

• Rotary shaft ho tiisa lesale ho thibela ho tsoa ha oli e tlotsang

• Setiiso sa lerole se tlatsitsoeng ka mafura (se nang le labyrinth le lamellar seal) ho lumella tšebetso ea

yuniti ea lisebelisoa libakeng tse lerōle haholo

Setiiso sa taconite se loketse ho sebelisoa libakeng tse lerōle

Mokhoa oa ho shebella boemo ba oli

Ho ipapisitsoe le tlhahiso ea taelo, yuniti ea gear e ka hlomelloa ka sistimi ea ho shebella boemo ba oli e thehiloeng ho sebali sa boemo, switch ea boemo kapa switch ea moeli oa ho tlatsa. Sistimi ea ho lekola boemo ba oli e etselitsoe ho lekola boemo ba oli ha yuniti ea gear e eme pele e qala.

Axial load monitoring

Ho itšetlehile ka tlhaloso ea taelo, yuniti ea gear e ka hlomelloa ka tsamaiso ea axial load monitoring system. Moroalo oa axial o tsoang sebokong sa seboko o hlahlojoa ke sele ea mojaro e hahiloeng. Hokela sena ho karolo ea tlhahlobo e fanoeng ke moreki.

Ho beha leihlo (ho beha leihlo ho thothomela)

Ho ipapisitse le litlhaloso tsa odara, yuniti ea gear e ka ba le li-sensor tsa vibration,

li-sensor kapa tse nang le likhoele bakeng sa lisebelisoa tse hokahanyang bakeng sa ho lekola li-bearings kapa li-gearing. U tla fumana leseli mabapi le moralo oa sistimi ea ho beha leihlo pampiring e arohaneng ea data litokomaneng tse felletseng tsa yuniti ea lisebelisoa.

E le mokhoa o mong, li-nipples tsa ho lekanya li ka kopanngoa le yuniti ea gear ho e lokisetsa monito