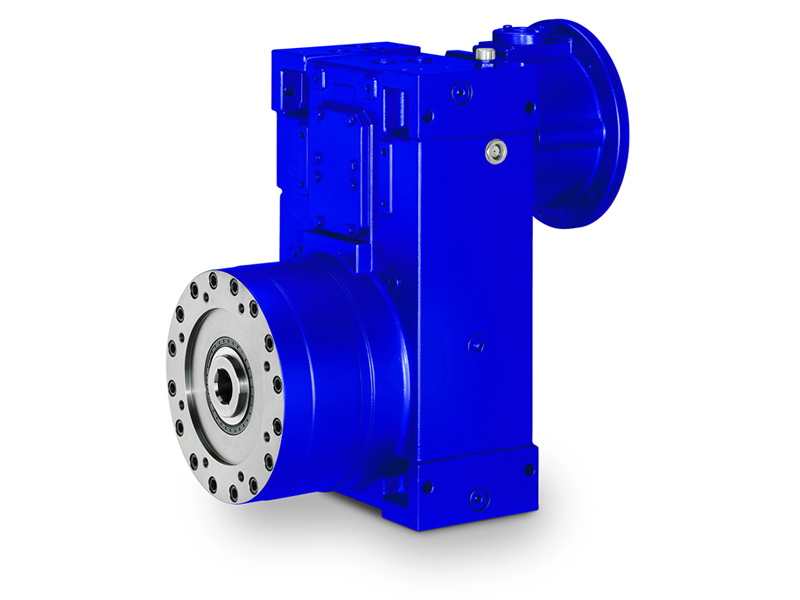

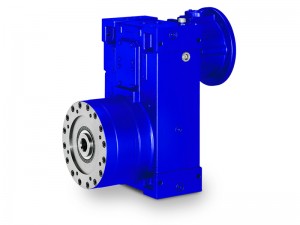

Single screw extruder gear units

Sizes:

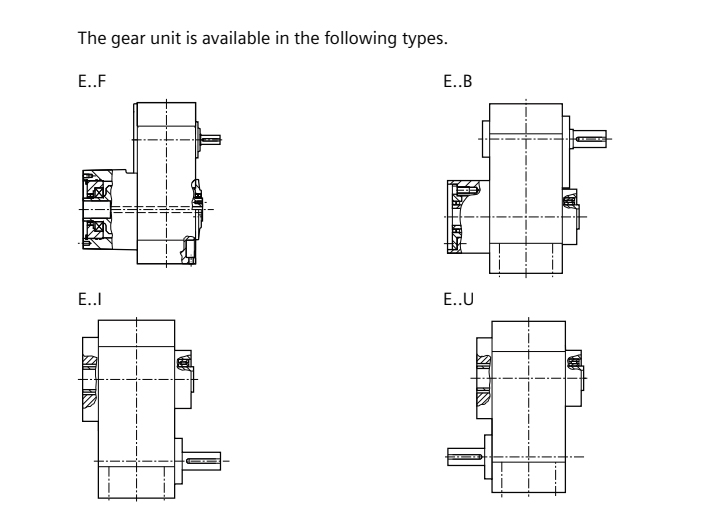

E2U E3U E4U E5U E6U E7U E8U E9U E10U E11U E12U

E2F E3F E4F E5F E6F E7F E8F E9F E10F E11F E12F

E2I E3I E4I E5I E6I E7I E8I E9I E10I E11I E12I

E2B E3B E4B E5B E6B E7B E8B E9B E10B E11B E12B

Compact design

Low noise emission

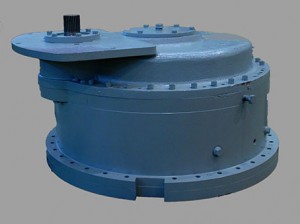

Highest axial forces possible due to thrust bearings fitted in front of the gear unit

Highest operational reliability due to thrust bearing in gear unit oil chamber

Reduced delivery times

SINGLE SCREW – MANY OUTPUT

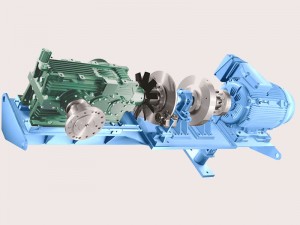

In the manufacture of rubber and plastics, the great variety of materials requires very high precision of the processing machines. Only then can the high expectations of customers regarding the final product be met. The high axial forces from the extrusion process must be absorbed. Our single screw extruder gear units are mainly used in plants for plastic forming, and are characterized by high operational reliability and short delivery times. The standard series comprises 2- and 3-stage helical or worm gear units with either integrated thrust bearings or thrust bearings fitted in front of the gear unit. Output torques from 6,300 to 173,000 Nm are possible.

Applications

Wide range of applications, e.g. for:

Rubber for conveyor belts

Automobile tires

Plastic film/sheets, e.g. packaging film, carrier bags, tarpaulins for fields

Cling film, food storage bags

Packaging (Tetra-Pak)

Thermal insulation boards (polystyrene)

Rotor blades for wind turbines

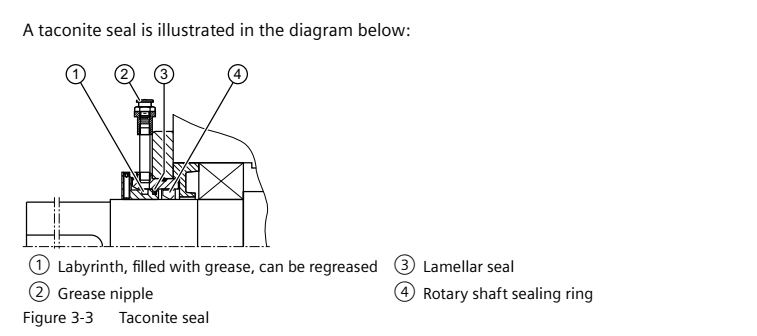

Taconite seal

The taconite seal is a combination of two sealing elements:

• Rotary shaft sealing ring to prevent the escape of lubricating oil

• Grease-filled dust seal (comprising a labyrinth and a lamellar seal) to allow operation of the

gear unit in extremely dusty environments

The taconite seal is ideal for use in dusty environments

Oil level monitoring system

Depending on the order specification, the gear unit can be equipped with an oil level monitoring system based on a level monitor, a level switch or a filling-level limit switch. The oil level monitoring system has been designed to check the oil level when the gear unit is at a standstill before it starts.

Axial load monitoring

Depending on the order specification, the gear unit can be equipped with an axial load monitoring system. The axial load from the worm shaft is monitored by a built-in load cell. Connect this to an evaluation unit provided by the customer.

Bearing monitoring (vibration monitoring)

Depending on the order specification, the gear unit can be equipped with vibration sensors,

sensors or with threads for connecting equipment for monitoring the rolling-contact bearings or gearing. You will find information about the bearing monitoring system design in the separate data sheet in the complete documentation for the gear unit.

As an alternative, measuring nipples can be attached to the gear units.