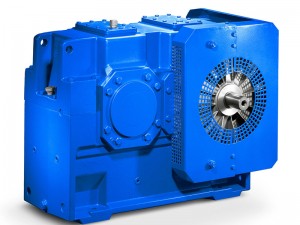

paper machine gear units

Home

Sizes:

H2PH04 H2PH05 H2PH06 H2PH07 H2PH08 H2PH09 H2PH10 H2PH11 H2PH12 H2PH13 H2PH14 H2PH15 H2PH16 H2PH17 H2PH18 H2PH19 H2PH20 H2PH21 H2PH22 H2PH23 H2PH24 H2PH25

B2PV04 B2PV05 B2PV06 B2PV07 B2PV08 B2PV09 B2PV10 B2PV11 B2PV12 B2PV13 B2PV14 B2PV15 B2PV16 B2PV17 B2PV18 B2PV19 B2PV20 B2PV21 B2PV22 B2PV23 B2PV24 B2PV25

K1N04 K1N05 K1N06 K1N07 K1N08 K1N09 K1N10 K1N11 K1N12 K1N13 K1N14 K1N15 K1N16 K1N17 K1N18 K1N19 K1N20 K1N21 K1N22 K1N23 K1N24 K1N25

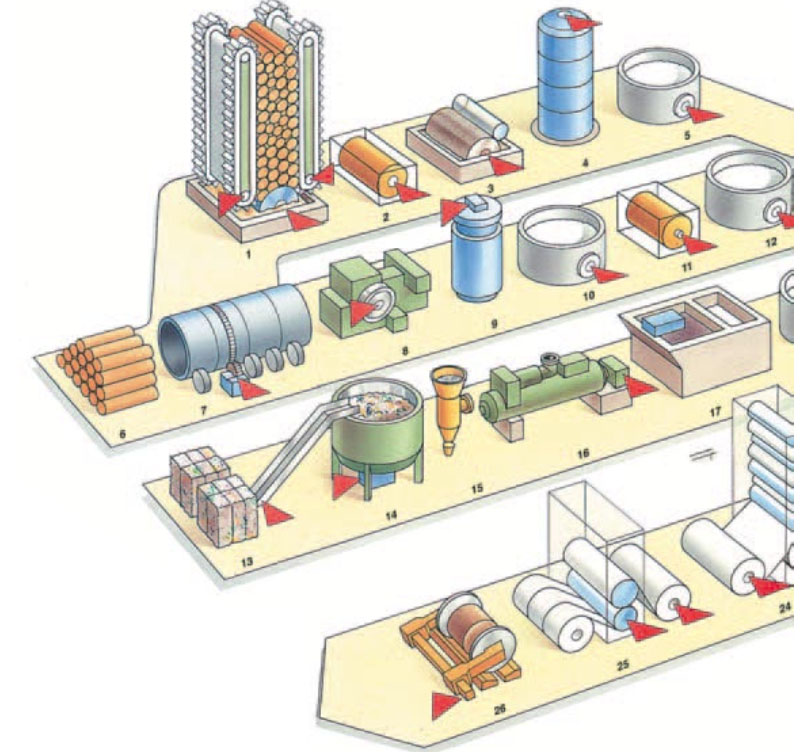

PAPER AND PULP PREPARATION SECTIONS

The drive units for papermaking and finishing plants vary considerably with regard to type and size. In most cases, the reason for this is not so much the size of the plant as the kind of paper to be made – such as board, newsprint, filter, money, or art paper, to name but a few.

Drawing on several decades of papermaking experience, we offer both standard and customized gear units for the most diverse applications in the paper industry: mechanical pulp, cellulose manufacture, waste paper recycling, dryer section, glazing rollers & M.G. cylinders, coating machines, calenders, and waste water purification plants.

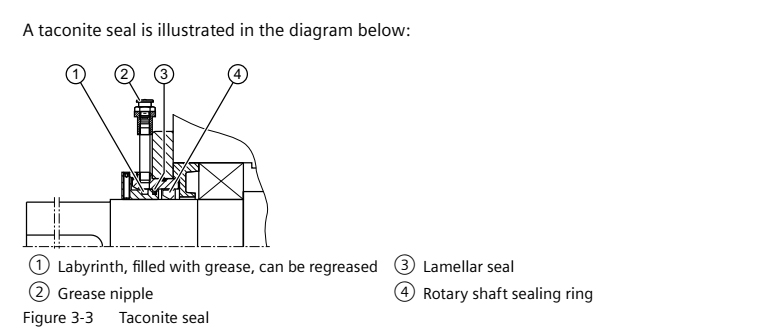

Taconite seal

The taconite seal is a combination of two sealing elements:

• Rotary shaft sealing ring to prevent the escape of lubricating oil

• Grease-filled dust seal (comprising a labyrinth and a lamellar seal) to allow operation of the

gear unit in extremely dusty environments

The taconite seal is ideal for use in dusty environments

Oil level monitoring system

Depending on the order specification, the gear unit can be equipped with an oil level monitoring system based on a level monitor, a level switch or a filling-level limit switch. The oil level monitoring system has been designed to check the oil level when the gear unit is at a standstill before it starts.

Bearing monitoring (vibration monitoring)

Depending on the order specification, the gear unit can be equipped with vibration sensors,

sensors or with threads for connecting equipment for monitoring the rolling-contact bearings or gearing. You will find information about the bearing monitoring system design in the separate data sheet in the complete documentation for the gear unit.

As an alternative, measuring nipples can be attached to the gear unit to prepare it for monitoring