iav units rau thoob elevator

• Muaj peev xwm muaj zog tshaj plaws

• Kev ntseeg siab ua haujlwm siab tshaj plaws

• Muaj ceev ceev

• Modular tsim qauv

Cov ntaub ntawv technical

Hom: Bevel helical iav chav tsev

Qhov ntau thiab tsawg: 15 qhov ntau thiab tsawg los ntawm 04 txog 18

No. of gear theem: 3

Kev ntsuas hluav taws xob: 10 txog 1,850 kW ( pabcuam tsav lub zog ntawm 0.75 txog 37 kW)

Kev sib kis: 25-71

Nominal torque: 6.7 txog 240 kNm

Mounting txoj hauj lwm: Kab rov tav

Txhim khu kev ntseeg Iav Units rau High Performance Vertical Conveyors

Cov thoob elevators ua haujlwm rau vertically thauj cov khoom loj ntawm cov khoom loj mus rau qhov siab sib txawv yam tsis tsim cov plua plav, ces muab pov tseg. Qhov siab yuav tsum tau kov yeej feem ntau ntau tshaj 200 meters. Qhov hnyav yuav txav mus los yog loj heev.

Cov khoom nqa hauv lub thoob lub elevator yog nruab nrab lossis ob txoj hlua txuas, txuas cov hlua, lossis siv cov thoob uas txuas nrog. Kev tsav tsheb yog nyob ntawm qhov chaw nres tsheb sab saud. Cov yam ntxwv uas tau teev tseg rau cov tsav tsheb uas tau teev tseg rau cov ntawv thov no zoo ib yam li cov khoom siv rau cov khoom siv thauj khoom hnyav. Cov thoob elevator xav tau lub zog sib piv siab. Lub tsav yuav tsum yog mos-pib vim lub siab pib lub zog, thiab qhov no yog tiav los ntawm cov kua couplings nyob rau hauv tsav tsheb ciav hlau. Bevel helical iav units feem ntau yog siv rau lub hom phiaj no raws li ib leeg lossis ntxaib tsav ntawm lub hauv paus ncej lossis viav vias puag.

Lawv yog cov yam ntxwv los ntawm qhov siab tshaj plaws kev ua tau zoo thiab kev cia siab rau kev ua haujlwm nrog rau kev pom zoo. Cov kev pabcuam pabcuam (kev tu lossis kev thauj khoom tsav) thiab cov backstops yog muab raws li tus qauv. Yog li ntawd, lub iav thiab lub auxiliary tsav yog zoo kawg nkaus matched.

Daim ntawv thov

Txiv qaub thiab cement kev lag luam

Hmoov

Cov chiv

Minerals thiab lwm yam.

Haum rau kev thauj khoom kub (txog 1000 ° C)

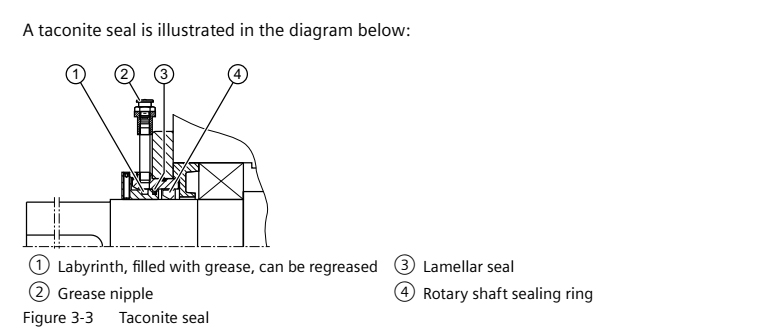

Taconite foob

Lub taconite foob yog ib qho ua ke ntawm ob lub sealing:

• Rotary ncej sealing nplhaib los tiv thaiv kev khiav ntawm lubricating roj

• Roj-filled plua plav foob (suav nrog lub labyrinth thiab lamellar foob) kom ua haujlwm ntawm

iav chav nyob hauv qhov chaw muaj plua plav heev

Lub taconite foob yog qhov zoo tagnrho rau siv hauv qhov chaw muaj plua plav

Roj qib xyuas qhov system

Nyob ntawm qhov kev txiav txim tshwj xeeb, lub iav chav tsev tuaj yeem nruab nrog cov roj ntsuas ntsuas ntsuas raws li qib ntsuas, qib hloov lossis hloov pauv hloov pauv. Cov roj qib xyuas qhov system tau tsim los xyuas cov roj qib thaum lub iav chav tsev nyob ntawm qhov chaw nres tsheb ua ntej nws pib.

Axial load xyuas

Nyob ntawm qhov kev txiav txim specification, lub iav chav tsev yuav nruab nrog ib tug axial load xyuas system. Lub axial load los ntawm tus cab cab yog saib xyuas los ntawm ib tug built-in load cell. Txuas qhov no mus rau chav ntsuas ntsuas los ntawm tus neeg siv khoom.

Bearing monitoring (kev vibration monitoring)

Nyob ntawm qhov kev txiav txim specification, lub iav chav tsev yuav nruab nrog vibration sensors,

sensors los yog nrog threads rau kev sib txuas cov cuab yeej rau kev soj ntsuam lub dov-hu rau bearings los yog gearing. Koj yuav pom cov ntaub ntawv hais txog kev saib xyuas cov kabmob tsim nyob rau hauv cov ntaub ntawv sib cais hauv cov ntaub ntawv ua tiav rau lub iav chav tsev.