Muab ob npaug rau ntsia hlau extruder iav units

Qhov ntau thiab tsawg:

61 G5070, 73 G 9000, 93 G 17850, 108G 28100, TG3. Qhov ntau thiab tsawg 50 txog 750

73 F txog 133 F qhov ntau thiab tsawg 7500 txog 45000

Iav chav tsev nrog lub zog ua haujlwm siab tshaj plaws

Lub sijhawm xa khoom luv ua tsaug rau kev ua qauv zoo ib yam ntawm cov vaj tsev thiab cov khoom sab hauv

Kev hloov kho qhov chaw nyob deb tuaj yeem ua tiav sai thiab nrog kev siv zog tsawg kawg nkaus thiab kev siv nyiaj.

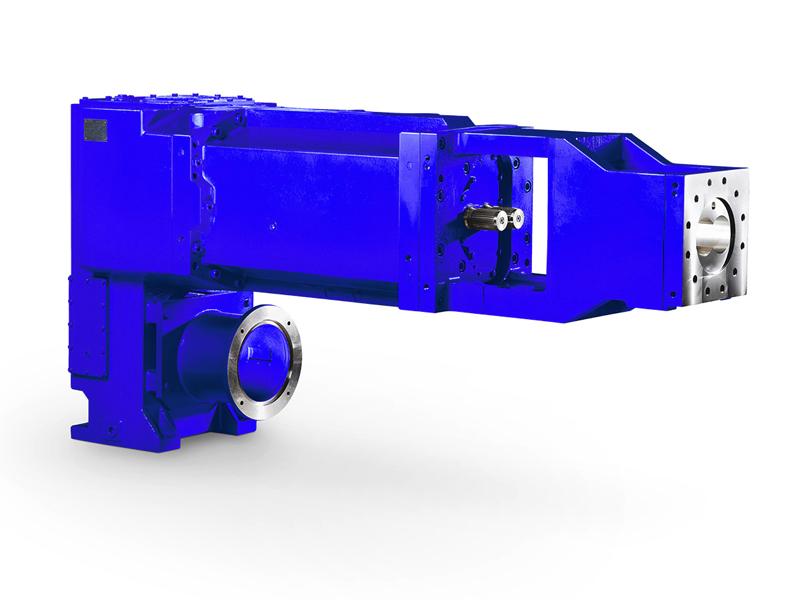

Helical iav units rau ob-ntsia hlau extruders nrog rau qhov sib txuas tsav shafts thiab tib cov kev taw qhia ntawm kev sib hloov ntawm cov ntsia hlau muaj nyob rau hauv ntau qhov ntau thiab tsawg hauv qhov kev ua tau zoo ntawm 200 thiab 35 000 Nm ib tus ncej thiab txog li 20 000 kW. Lawv feem ntau yog siv rau hauv kev tsim cov granulates thiab refining ntawm raw plastics raws li nyob rau hauv cov xim thiab lacquer kev lag luam thiab nyob rau hauv lub ntxhua khaub ncaws, khoom noj khoom haus thiab tsiaj noj industries.

Extruder iav units yog qhov zoo tshaj plaws tsav nyob rau hauv txhua rooj plaub, vim hais tias lawv yog high-kev ua tau zoo thiab txhim khu kev qha. Vim lawv lub neej ua haujlwm ntev thiab lawv xav tau kev ua haujlwm me me, lawv sawv cev rau kev daws teeb meem kev lag luam thoob ntiaj teb.

Helical iav units rau ob-ntsia hlau extruders kuj tsis tshua muaj qauv thiab tso cai rau cov neeg siv khoom tshwj xeeb teeb tsa yam tsis muaj teeb meem. Piv txwv li kev hloov kho qhov chaw nyob deb tuaj yeem pom tau nrog kev siv dag zog thiab kev siv nyiaj tsawg heev, yog li ua kom tus nqi-optimized cov neeg siv khoom tshwj xeeb.

Ob chav ntsia hlau extruder (synchronous)

Yuav kom nqus tau cov torques siab heev thiab axial rog teeb tsa los ntawm cov txheej txheem extrusion, peb tau tsim ib qho extruder iav chav tsev nrog ob lub zog-splitting system thiab tshwj xeeb thrust bearings. Cov kabmob muaj peev xwm muaj txog li yim thrust bearings txheej ib sab tom qab. Tso zis torques ntawm 200 mus rau 35,000 Nm thiab nruab nrab nrug ntawm 18.3 thiab 140 mm yuav realised. Tsis tas li ntawd peb tuaj yeem muab cov kev daws teeb meem rau cov neeg siv khoom txog li 20,000 kW.

Daim ntawv thov

Helical iav chav nyob rau ob-ntsia hlau extruders nrog rau lub tog raj kheej tsav shafts thiab tib cov kev taw qhia ntawm cov ntsia hlau rotation yog siv nyob rau hauv lub tsim ntawm granulates thiab refining ntawm raw plastics. Lwm thaj chaw ntawm kev thov suav nrog:

Kev lag luam xim thiab lacquer

Kev lag luam ntxhua khaub ncaws

Khoom noj khoom haus kev lag luam (xws li qhob cij, pasta)

Tsiaj-feed kev lag luam (dog, miv lwm yam tsiaj noj)

Ob chav ntsia hlau extruder (contra-rotatory)

Nyob rau hauv lub tshav pob ntawm extrusion, nrog rau co-rotatory ob-ntsia hlau extruder iav units, peb kuj muab contra-rotatory ob-ntsia hlau extruder iav units nyob rau hauv ntsug thiab kab rov tav versions. Center nrug ntawm 60 thiab 140 mm thiab tso zis torques ntawm 5,000 thiab 60,000 Nm yuav realised.

Daim ntawv thov

Cov kav dej (cov kav dej khib nyiab, cov kav dej hauv av, cov kav dej tso cua)

Profiles

Qhov rai ncej

Sidings

Foils

Cov khoom ntim

Kub-insulating boards

Rotor hniav rau cua turbines

Log tsheb

Cov kab sib dhos

Conveyor siv

Fittings rau automotive kev lag luam

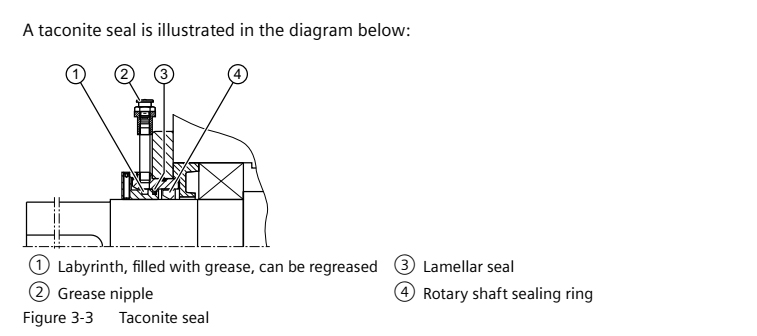

Taconite foob

Lub taconite foob yog ib qho ua ke ntawm ob lub sealing:

• Rotary ncej sealing nplhaib los tiv thaiv kev khiav ntawm lubricating roj

• Roj-filled plua plav foob (suav nrog lub labyrinth thiab lamellar foob) kom ua haujlwm ntawm

iav chav nyob hauv qhov chaw muaj plua plav heev

Lub taconite foob yog qhov zoo tagnrho rau siv hauv qhov chaw muaj plua plav

Roj qib xyuas qhov system

Nyob ntawm qhov kev txiav txim tshwj xeeb, lub iav chav tsev tuaj yeem nruab nrog cov roj ntsuas ntsuas ntsuas raws li qib ntsuas, qib hloov lossis hloov pauv hloov pauv. Cov roj qib xyuas qhov system tau tsim los xyuas cov roj qib thaum lub iav chav tsev nyob ntawm qhov chaw nres tsheb ua ntej nws pib.

Axial load xyuas

Nyob ntawm qhov kev txiav txim specification, lub iav chav tsev yuav nruab nrog ib tug axial load xyuas system. Lub axial load los ntawm tus cab cab yog saib xyuas los ntawm ib tug built-in load cell. Txuas qhov no mus rau chav ntsuas ntsuas los ntawm tus neeg siv khoom.

Bearing monitoring (kev vibration monitoring)

Nyob ntawm qhov kev txiav txim specification, lub iav chav tsev yuav nruab nrog vibration sensors,

sensors los yog nrog threads rau kev sib txuas cov cuab yeej rau kev soj ntsuam lub dov-hu rau bearings los yog gearing. Koj yuav pom cov ntaub ntawv hais txog kev saib xyuas cov kabmob tsim nyob rau hauv cov ntaub ntawv sib cais hauv cov ntaub ntawv ua tiav rau lub iav chav tsev.

Raws li lwm txoj hauv kev, ntsuas lub txiv mis tuaj yeem txuas rau lub iav chav tsev los npaj nws rau monito