conveyor tsav assemble

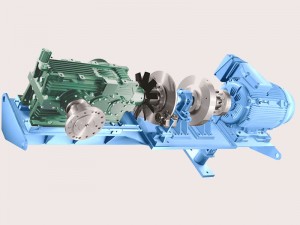

Conveyor tsav assemble muaj xws li:

1. gearbox

2. Tsawg ceev tso zis couplings

3. Pa los yog kua hom input couplings

4. Tuav / nraub qaum

5. Disc lossis nruas nres

6. Fan

7. Cov neeg saib xyuas kev nyab xeeb

8. Fly wheel (inertia log) nrog ywj siab txhawb nqa bearings

9. Hluav taws xob cov motors (HV lossis LV)

10. Base ncej nyob rau hauv pem teb mounted, viav vias puag los yog qhov mount versions nrog torque caj npab

11. Output coupling guard

Conveyor siv tsav - Nta & Cov txiaj ntsig

- · Kev ntsuas hluav taws xob txog li 2000KW, nrog rau kev hloov kho kev tsav tsheb sib dhos rau kev xav tau ntau dua

- · Lub neej ntev - feem ntau tshaj 60,000 teev

- · Tsawg suab nrov thiab kev co

- · Muaj peev xwm ua kom muaj cua sov los ntawm kev tsim cov cua txias tshiab

- · Tiv tauj thiab tsis tiv tauj cov kev xaiv sealing

Optimized conveyor tsav systems muaj xws li:

- · conveyor gearbox

- · Tsawg ceev tso zis couplings

- · Pa los yog kua hom input couplings

- · Ncua tseg / rov qab

- · Disc lossis nruas nres

- · Fan

- · Cov neeg saib xyuas kev nyab xeeb

- · Fly wheel (inertia log) nrog ywj siab txhawb nqa bearings

- · Fais motors (HV lossis LV)

- · Lub hauv paus ncej hauv pem teb mounted, viav vias puag lossis qhov mount versions nrog torque caj npab

- · Output coupling tiv thaiv

| Chav tsev | Hom lub cev muaj zog * |

| CX210 | 55 kW ib |

| CX240 | 90 kW ib |

| xwm 275 | 1 32 kWm |

| CX300 | 160 kW |

| xwm 336 | 250 kW ib |

| xwm 365 | 3 15 kWm |

| CX400 | 400 kW |

| xwm 440 | 500 kW |

| xwm 480 | 7 10 kWm |

| xwm 525 | 800 kW ib |

| xwm 560 | 1,120 kW tsi |

| xwm 620 | 1,250 kW tsi |

| xwm 675 | 1,600 kW |

| xwm 720 | 1,800 kW |

| CX800 | 2,000 kW |

Cov koob no muaj qhov tshwj xeeb ua pov thawj qib ntawm kev ua tau zoo, ntau yam thiab lub neej expectancy, uas tshaj qhov xav tau ntawm cov ntawv thov niaj hnub conveyor thiab

ua haujlwm kom ua tiav qhov muaj nyob ntawm peb cov neeg siv khoom cov txheej txheem txhua qhov chaw lawv nyob hauv lub ntiaj teb.

Txhim kho thermal muaj peev xwm

Kev txhim kho thermal kev ua tau zoo ntawm cov gearboxes tau raug sim ntau, ob qho tib si nrog kev sim hauv qee qhov chaw kub siab tshaj plaws ntawm qhov chaw mining, nrog rau cov kev tswj xyuas ntawm peb tus kheej lub txaj kuaj mob.

Txhim kho cov kabmob lub neej

Theoretical bearing lub neej tsuas yog ua tiav nyob rau hauv kev xyaum los ntawm ib tug zoo tsim gearbox configuration thiab txaus lubrication. Kev sim ntau yam qauv ua tiav ntawm cov koob no, rov qab los ntawm kev paub dhau los, txhais tau hais tias tus neeg siv tuaj yeem ntseeg tau tias lub neej xav tau tuaj yeem ua tiav. Qhov no ua rau peb cov neeg siv khoom kom tsis txhob muaj kev puas tsuaj uas tsis tau npaj tseg, thaum kawg ua rau cov nqi kho mob qis dua.

Txhim kho thiab optimized lubrication tsim

Kev sim ntau yam qauv tau ua kom ntseeg tau tias qhov yooj yim sab hauv lubrication tsim yog ua haujlwm thoob plaws ntau yam kev khiav hauj lwm kub, gearbox orientations thiab khiav ceev. Nrog rau kev siv cov kev hloov pauv ceev ceev rau cov khoom siv thauj khoom nws yog qhov tseem ceeb uas cov neeg siv tuaj yeem ntseeg tau tias lawv cov tsav tau raug lubricated txaus, txawm tias thaum khiav ntawm qhov nrawm nrawm. Pib los ntawm cov roj txias txias tau simulated los xyuas kom meej tias txawm tias thaum kub kub pib, tag nrho cov bearings thiab iav yog lubricated txaus.

Tsawg suab nrov, kev ua haujlwm siab

Nrog lub suab nrov ua paug ua ib qho tseem ceeb ntxiv rau hauv kev qhia tshwj xeeb thiab tsim cov tshuab ua haujlwm, gearboxes tsim rau cov suab nrov qis yog qhov yuav tsum tau ua. Cov koob no suav nrog cov qauv tsim tshiab thiab tsim cov thev naus laus zis los txhim kho kev ua haujlwm zoo rau kev ua haujlwm tsis muaj suab nrov, nrog rau cov txiaj ntsig theoretical tau raug txheeb xyuas los ntawm kev ntsuas qhov ntsuas qhov ntsuas qhov ntsuas thiab nws tus kheej ntsuas lub suab nrov.