Don lubrication na buɗaɗɗen kayan aiki da ake amfani da su a aikace-aikacen masana'antu daban-daban kamar suminti da masana'antar kwal, tanderun rotary, ko kuma inda yanayin rufewa ke da wahala, ana amfani da man shafawa mai ɗanɗano kaɗan maimakon mai. Don aikace-aikacen girth gear ana amfani da man shafawa tare da fantsama ko tsarin fesa mai. Zaɓin irin waɗannan mayukan yana yin tasiri ga rayuwar lokaci-lokaci da ƙarfin ɗaukar kaya na kayan aiki, da kuma halayen sawa.

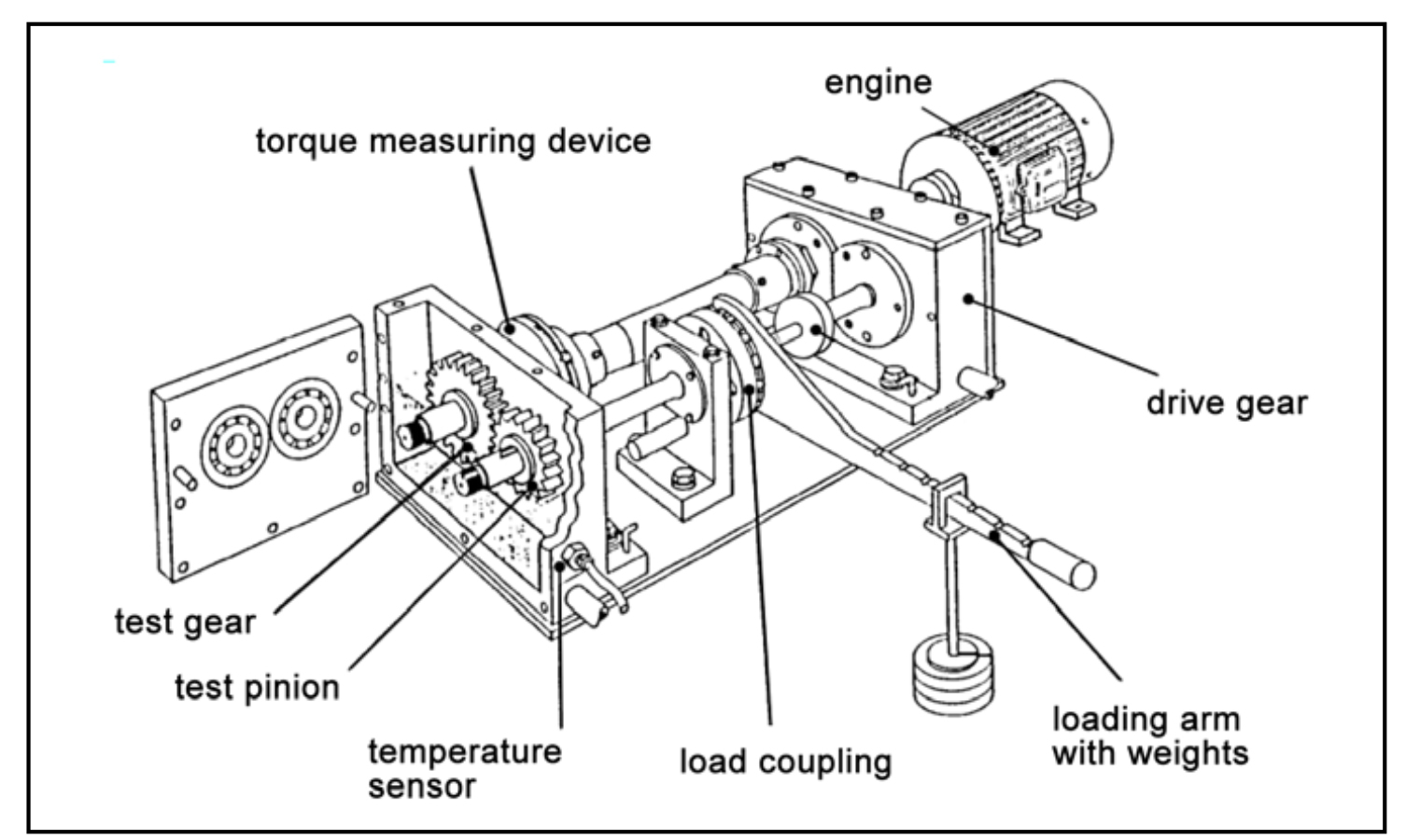

An gudanar da bincike da yin kwatance tsakanin mai ruwa da daban-daban Semi-ruwa formulations (NLGI00), bambanta dangane da tushe danko mai, thickener nau'i da ƙari na duka biyu ruwa da kuma m Additives. Gwajin gwajin don ƙayyade sigogi daban-daban an yi su a kan kayan aikin gwaji na baya-baya; Ana nuna saitin tsarin na'urar gwajin a ƙasa.

Sakamakon gwajin ya nuna cewa man shafawa na NLGI 00 daidai yake yana nuna kusan rayuwa iri ɗaya kamar takwarorinsu na tushen mai. Bugu da ƙari, dankon kinematic na tushen mai yana nuna tasiri mai mahimmanci akan pitting rayuwa na irin nau'in man shafawa na NLGI 00. Bugu da kari na musamman roba graphite zuwa irin wannan gear man shafawa ya haifar da raguwa a cikin pitting rayuwa da kuma high lalacewa. Sakamakon gwajin ya kuma nuna cewa nauyin da ke ɗauke da ƙarfin waɗannan mayukan yana da alaƙa da ɗanɗanon kinematic na tushen mai. Yin amfani da danko mai tushe mafi girma, an sami tsayin rami mai tsayi da mafi girman nauyin ɗaukar kaya. Don man shafawa na rabin-ruwa, ƙididdige nauyin ɗaukar nauyi bisa ga ISO 6336 ta amfani da danko na tushen mai yana da alaƙa da sakamako mai amfani. Gwaje-gwaje don nazarin halayen lalacewa na nau'ikan mai mai-mai-ruwa daban-daban an yi su a cikin gwajin lalacewa A / 2.8 / 50 bisa tushen ISO 14635-3 da ISO 14635-1. An fayyace nau'ikan sutura daban-daban guda huɗu don gwajin jimrewa na sa'o'i 100 da rarrabuwa bisa ga jimillar lalacewa a kan pinion da dabaran. Gabaɗaya magana, kusan dukkanin man shafawa da aka bincika, ban da mai da ke ɗauke da mai mai ƙarfi, suna nuna ƙarancin lalacewa a duk sassan gwaji. Za'a iya ganin tasirin dankon mai tushe a cikin wannan greases tare da babban danko mai tushe yana nuna ƙananan lalacewa. Tasirin maida hankali mai kauri da nau'in mai kauri kusan ba ya da kyau, amma man shafawa mai hadadden sabulun aluminium yana nuna ɗan ƙaramin ƙarar lalacewa idan aka kwatanta da ɓangaren sabulun sabulun lithium. Ana iya ganin bambanci mai mahimmanci a cikin tasirin adadin da nau'in mai mai mai ƙarfi. Man shafawa da ke ɗauke da graphite na roba suna nuna ƙimar lalacewa da yawa - daidaitawa da adadin graphite a cikin mai - idan aka kwatanta da maiko iri ɗaya ba tare da ƙoshin mai ba. A ƙarshen gwajin maiko mai ɗauke da 4.2% graphite yana nuna adadin lalacewa sau uku fiye da mai mai tushe. Kuma tare da mafi girman adadin graphite - 11.1% - jimlar lalacewa ta ƙaru zuwa matakin sau takwas mafi girma idan aka kwatanta da mai ba tare da daskararru ba. An kuma tabbatar da wannan yanayin a gwajin juriya; watau - mafi yawan graphite, mafi girma da lalacewa. A gefe guda, mai mai ɗauke da 4.2% na molybdenum disulphide yana nuna irin lalacewa. Lokacin da spur gearset ya fara juyawa, maiko kusa da gearset za a watsar da shi nan da nan kuma baya komawa wannan kayan aikin saboda rashin isassun ingantacciyar hanyar sake cikawa. An samu tazara tsakanin injinan jujjuyawar da man mai. Babu wani sabon mai da ke gudana daga sump zuwa gearset saboda tsayayyen daidaitonsa. Ana iya lura da rashin lubrication da sanyaya wanda zai iya haifar da yanayin zafi mai yawa a cikin gears kuma, a ƙarshe, zuwa kullun. Ƙananan adadin man shafawa ne kawai ke shiga cikin lubrication. Tashoshi yana faruwa galibi a matakan cikawa na 40 da 50% kuma don ƙwaƙƙwaran prod zuwa mai mai tushe bayan gwajin mataki kuma ɗan ƙaramin lalacewa bayan gwajin jimiri.

A cikin wani mahallin daban-daban, don lubrication na ƙananan, keɓaɓɓen kayan aiki da aka yi amfani da su a cikin kayan aikin lantarki ko a cikin aikace-aikacen likita, kazalika don lubrication na ƙananan akwatunan gear a cikin mawuyacin yanayin rufewa, an fi son mai mai ƙarfi, galibi na daidaiton darajar NLGI 1 ko 2. . Zaɓin nau'in maiko da matakin cikawa yana tasiri tasiri, ƙarfin ɗaukar nauyi da canja wurin zafi a cikin akwati.

Lokacin aikawa: Agusta-10-2021