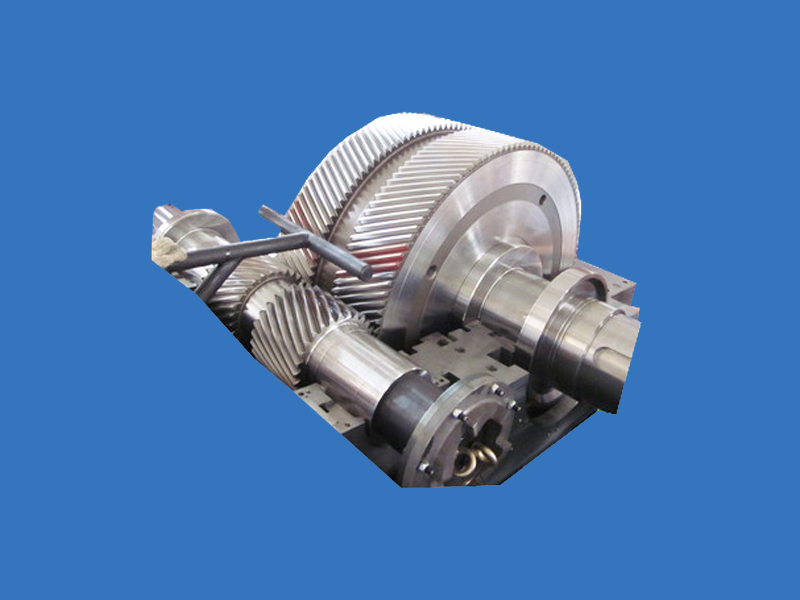

girth gear gearbox double helix

Product Parameters

|

Ratio(i) |

1 |

|

Input speed(r/min) |

35~120 |

|

Output center distance(mm) |

750~900 |

|

Maximum output torque(kN.m) |

1050~3275 |

Product Description

The industrial double helical tooth gear units (gearboxes, speed reducer)

It’s suitable for industry of metallurgy, extracting sugar, rubber and so on, which has high rigidity; resistance to impact, transmitting large torque and two-way work frequently.

The working temperature of the gearbox ranges from -40 to 45. When the ambient temperature is lower the 8, preheating the lubrication before operating. When the ambient temperature around is above 35, cooling system should be added.

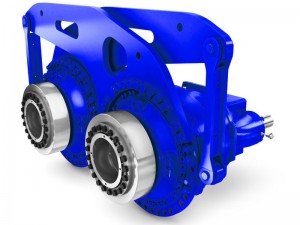

The gearbox features compact structure, light weight, small volume, and high ability of load, low noise and vibration.

The gearbox can achieve test of temperature and vibration automatically.

The gear is manufactured by high-quality alloy steel with carburizing and quenching. The tooth surface hardness is HRC57+4. The gear is modified with serrated form. The class of precision is 5-6 (DIN).

The case’s structural style is vertical split structure which is combined with high intensity bolt, which is manufactured conveniently and fine appearance. The case is welded manufactured which is annealed after welding. The case will be dealt with aging treatment in order to eliminate residual stress. So, the case deforms hardly.

The gearbox adopts mechanical sealing, which has good effect. The sealing structure is reliable and non-maintaining.

The gearbox uses forced spray oil lubrication, the lubrication pipelines is distributed in or out of the gearbox, which can lubricate the gear and bearing sufficiently. The oil inlet and the oil discharge mouth are mounted on the gearbox. The pressure switch, the flux monitor and the cut-off valve are mounted near the oil inlet. The pressure switch and the flux monitor can monitor the oil supply and feed back the pressure and flux signal which is switch quantity or analog quantity to primary control system.