China Best Famous Varibloc Gear Unit Companies - cooling tower gear units – Intech

China Best Famous Varibloc Gear Unit Companies - cooling tower gear units – Intech Detail:

Sizes:

H2NV05 H2NV06 H2NV07 H2NV08 H2NV09 H2NV10 H2NV11 H2NV12 H2NV13 H2NV14 H2NV15 H2NV16

H3NV05 H3NV06 H3NV07 H3NV08 H3NV09 H3NV10 H3NV11 H3NV12 H3NV13 H3NV14 H3NV15 H3NV16

B3NV05 B3NV06 B3NV07 B3NV08 B3NV09 B3NV10 B3NV11 B3NV12 B3NV13 B3NV14 B3NV15 B3NV16

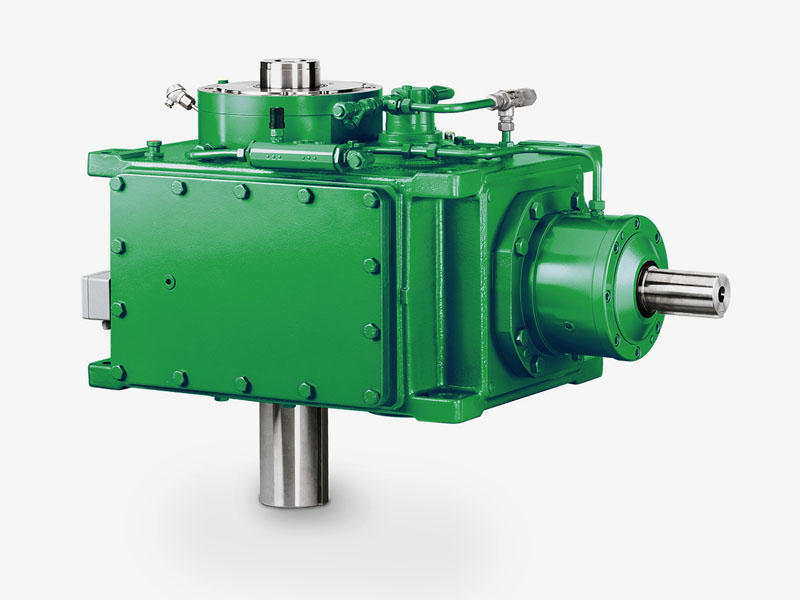

• Low noise emission due to torsionally rigid housings

• Variable dimensions of the output bearings for the different ventilator types (according to the ventilating rail)

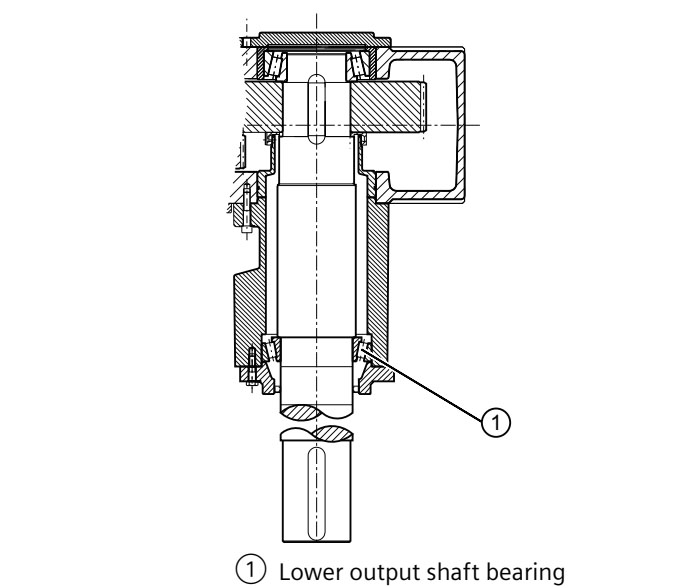

• Highest operational reliability due to one-part housings, reinforced bearings, centrifugal discs on the ventilator shaft

• Additional cooling realized by fan cooler on the input shaft

• Long service life as a result of optimized gear unit selection and use of high-grade materials

• Complete drive system from a single source

CALMING EFFECT : OPERATIONAL RELIABILITY EVEN IN CASE OF THE HIGHEST VENTILATION FORCES

Wet Cooling Towers are those buildings where the water that was heated by industrial or power generation processes is cooled, again. The heat is given off to the environment. Wet cooling towers are an integral part of the thermodynamic circle. The water to be cooled is sprayed and distributed over the splash fills. As a result the water temperature drops when the evaporation heat is withdrawn and the air gets humified.

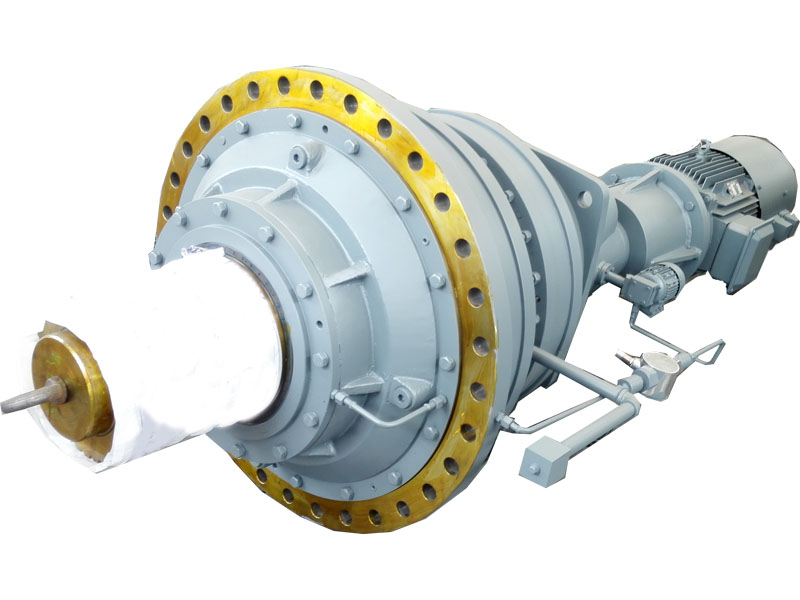

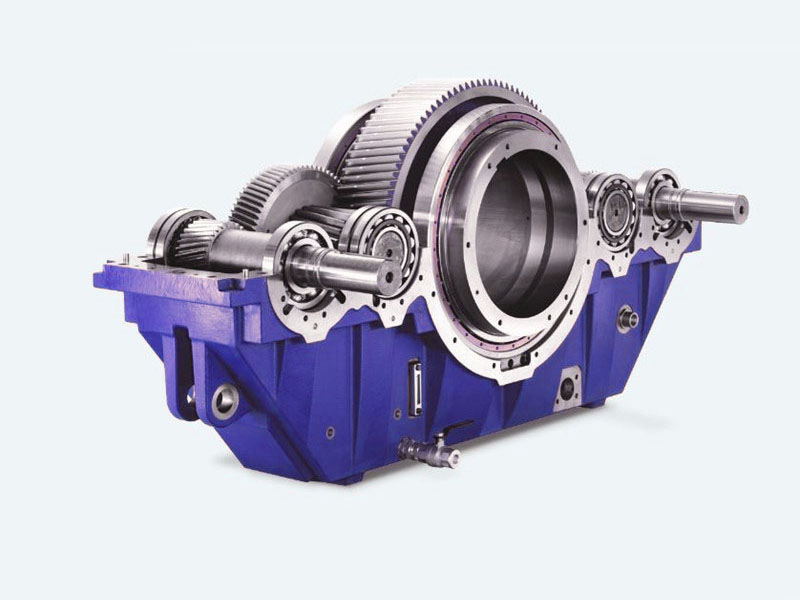

The required air stream for the cooling is produced by ventilators which are mounted on an output shaft of the gear unit. To enable the Wet Cooling Tower Gear Units to absorb the enormous ventilation forces the gear units are equipped with an additional axial bearing. Therefore, only application-adapted 2-staged bevel helical gear units are used to fulfill the special requirements of this application.

The motor is installed outside the cooling tower. He is mechanically connected to the gear unit that is placed right in the middle of the diffuser of the cooling tower via long Composite Couplings.

Applications

Power generating industries, like.:

• Biomass power plant

• Gas power plant

• Waste incineration plant

• Oil power plant

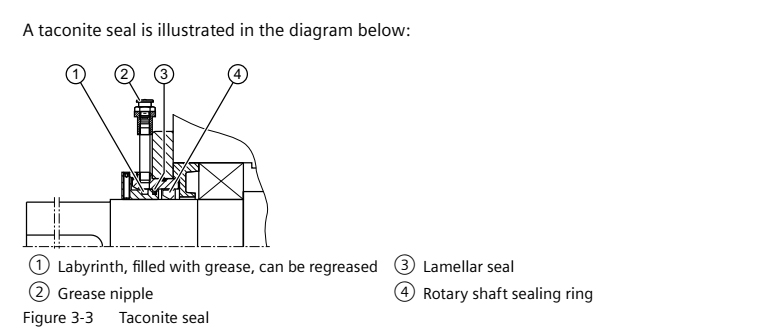

Taconite seal

The taconite seal is a combination of two sealing elements:

• Rotary shaft sealing ring to prevent the escape of lubricating oil

• Grease-filled dust seal (comprising a labyrinth and a lamellar seal) to allow operation of the

gear unit in extremely dusty environments

The taconite seal is ideal for use in dusty environments

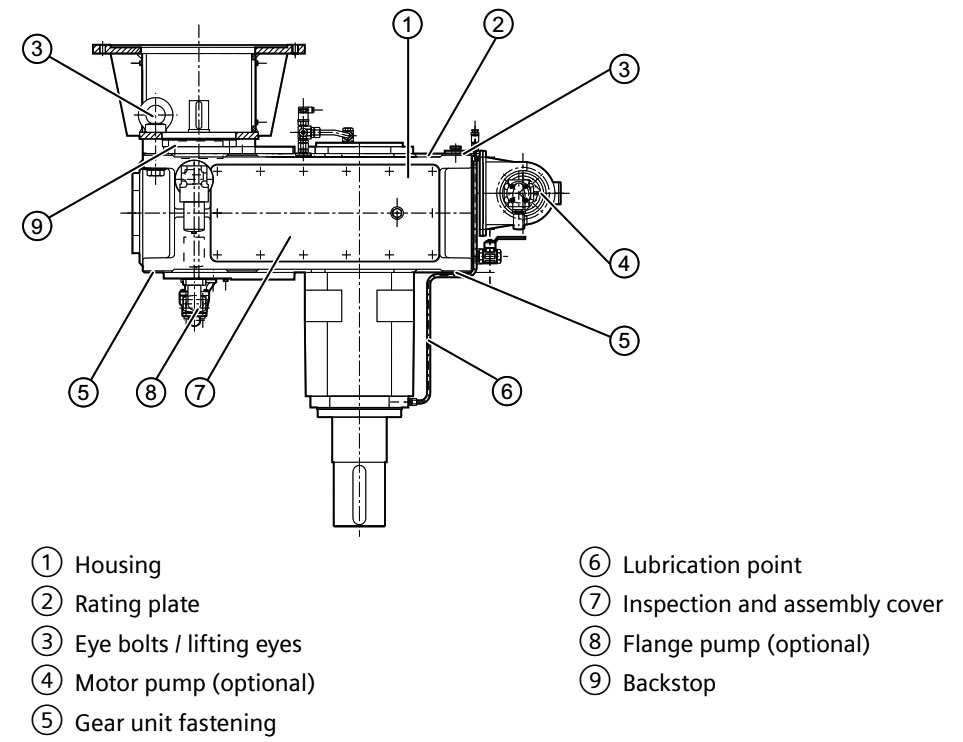

Oil level monitoring system

Depending on the order specification, the gear unit can be equipped with an oil level monitoring system based on a level monitor, a level switch or a filling-level limit switch. The oil level monitoring system has been designed to check the oil level when the gear unit is at a standstill before it starts.

Axial load monitoring

Depending on the order specification, the gear unit can be equipped with an axial load monitoring system. The axial load from the worm shaft is monitored by a built-in load cell. Connect this to an evaluation unit provided by the customer.

Bearing monitoring (vibration monitoring)

Depending on the order specification, the gear unit can be equipped with vibration sensors,

sensors or with threads for connecting equipment for monitoring the rolling-contact bearings or gearing. You will find information about the bearing monitoring system design in the separate data sheet in the complete documentation for the gear unit.

As an alternative, measuring nipples can be attached to the gear unit to prepare it for monitoring

Product detail pictures:

Related Product Guide:

Cooperation

As for competitive prices, we believe that you will be searching far and wide for anything that can beat us. We can state with absolute certainty that for such quality at such prices we are the lowest around for China Best Famous Varibloc Gear Unit Companies - cooling tower gear units – Intech, The product will supply to all over the world, such as: Cambodia, Pretoria, Dubai, We've a good reputation for stable quality solutions, well received by customers at home and abroad. Our company would be guided by the idea of "Standing in Domestic Markets, Walking into International Markets". We sincerely hope that we could do business with customers both at home and abroad. We expect sincere cooperation and common development!

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.