China Best Famous Rolling Mill Gearbox Suppliers - conveyor drive assemble – Intech

China Best Famous Rolling Mill Gearbox Suppliers - conveyor drive assemble – Intech Detail:

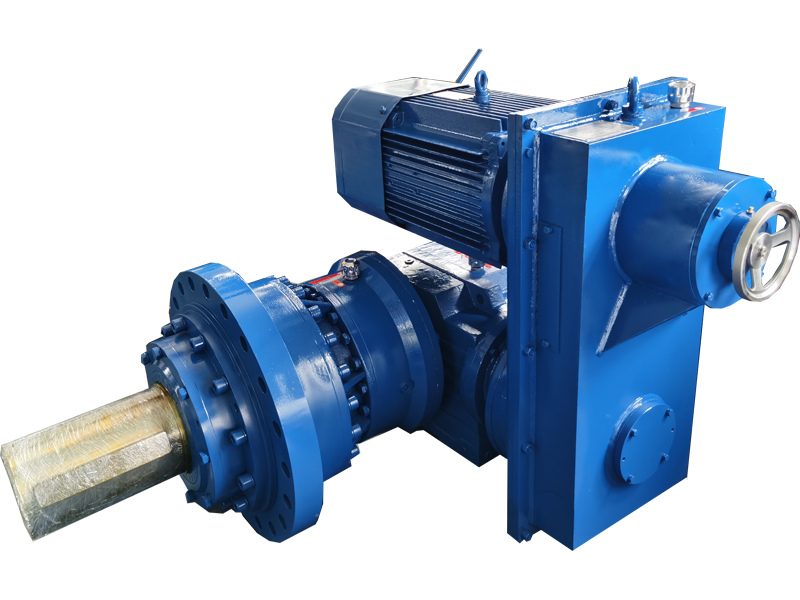

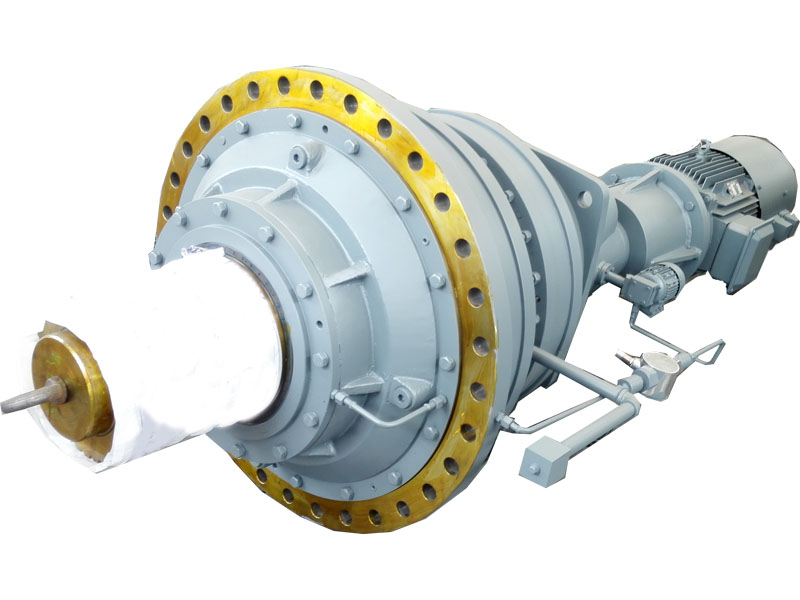

Conveyor drive assemble includes:

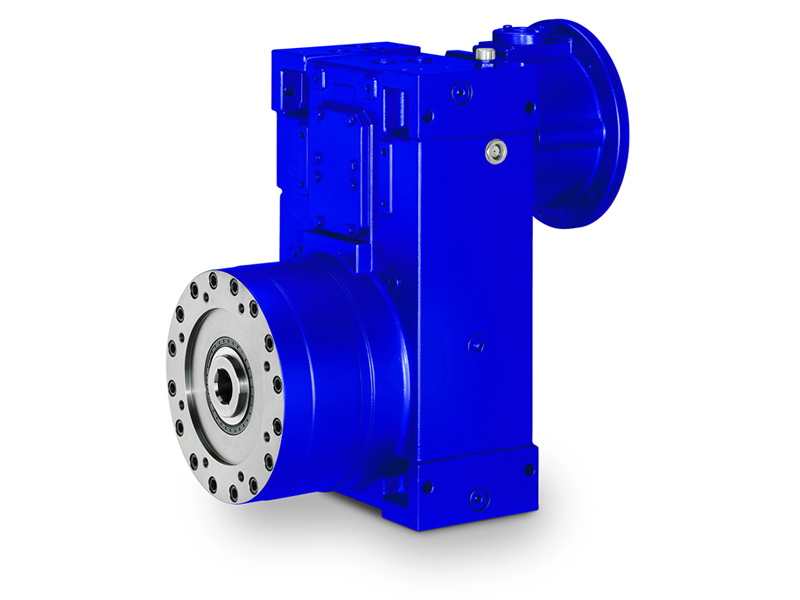

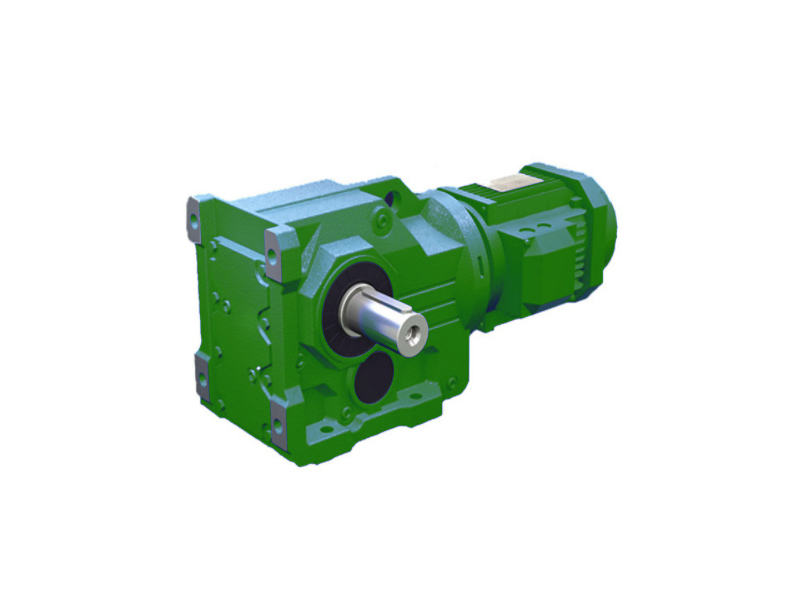

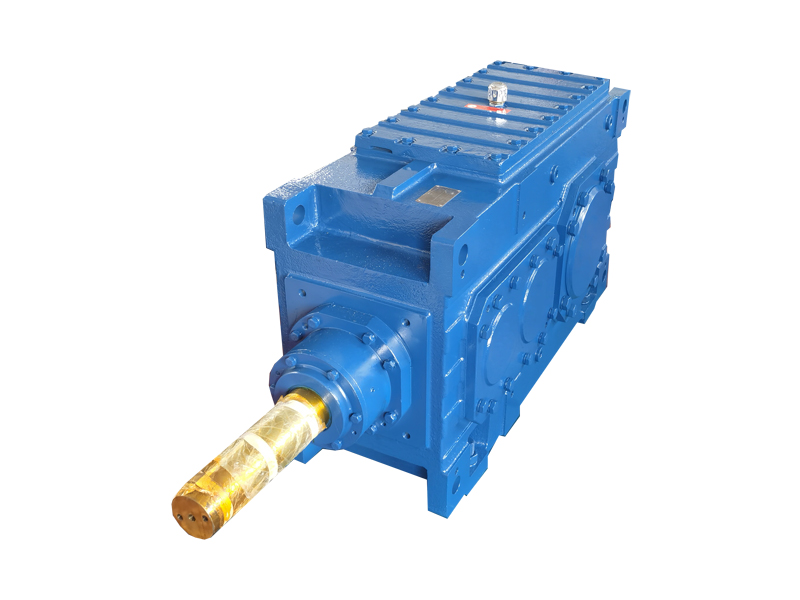

1. gearbox

2. Low speed output couplings

3. Conventional or fluid type input couplings

4. Holdback/backstop

5. Disc or drum brakes

6. Fan

7. Safety guards

8. Fly wheel (inertia wheel) with independent support bearings

9. Electrical motors (HV or LV)

10. Base frame in floor mounted, swing base or tunnel mount versions with torque arm

11. Output coupling guard

Conveyor belt drives – Features & Benefits

- · Power ratings up to 2000KW , with customised conveyor drive assembly options for higher power requirements

- · Long bearing life – typically in excess of 60,000 hours

- · Low noise and vibration

- · High thermal capacity via a new cooling fin design

- · Contacting and non-contacting sealing options

Optimised conveyor drive systems include:

- · conveyor gearbox

- · Low speed output couplings

- · Conventional or fluid type input couplings

- · Holdback / backstop

- · Disc or drum brakes

- · Fan

- · Safety guards

- · Fly wheel (inertia wheel) with independent support bearings

- · Electric motors (HV or LV)

- · Base frame in floor mounted, swing base or tunnel mount versions with torque arm

- · Output coupling guard

|

Unit |

Typical motor power * |

|

CX210 |

55kW |

|

CX240 |

90kW |

|

CX275 |

132kW |

|

CX300 |

160kW |

|

CX336 |

250kW |

|

CX365 |

315kW |

|

CX400 |

400kW |

|

CX440 |

500kW |

|

CX480 |

710kW |

|

CX525 |

800kW |

|

CX560 |

1,120kW |

|

CX620 |

1,250kW |

|

CX675 |

1,600kW |

|

CX720 |

1,800kW |

|

CX800 |

2,000kW |

This series offers exceptional field proven levels of performance, versatility and life expectancy, which exceed the demanding requirements of modern conveyor applications and

work to maximise the availability of our customers’ processes wherever they are in the world.

Enhanced thermal capacity

The improved thermal performance of the gearboxes has been extensively tested, both with field trials in some of the highest ambient temperature mining environments, as well as under controlled conditions on our own dedicated test beds.

Improved bearing life

Theoretical bearing lives can only be achieved in practice by a well designed gearbox configuration and adequate lubrication. The extensive prototype testing carried out on this series, backed up by field experience, means that the user can be confident that the desired bearing lives can be achieved. This enables our customers to avoid unplanned outages, ultimately leading to lower maintenance costs.

Improved and optimised lubrication design

Extensive prototype testing has ensured that the simple internal lubrication design is functional across a wide range of operating temperatures, gearbox orientations and running speeds. With increasing use of variable speed drives for conveyors it is essential that users can be confident that their drives are being adequately lubricated, even when running at creep speeds. Start ups from cold oil conditions have been simulated to ensure that even at low temperature start up, all bearings and gears are adequately lubricated.

Low noise, high performance

With noise pollution being an ever increasing factor in the specification and design of industrial machinery, gearboxes designed for low noise are a must. The series incorporates the latest design and manufacturing technologies to optimise gearing for low noise operation, with the theoretical results being verified by thorough test rig testing and independently verified noise measurements.

Product detail pictures:

Related Product Guide:

Cooperation

Sticking to the principle of "Super High-quality, Satisfactory service" ,We are striving to generally be a very good business partner of you for China Best Famous Rolling Mill Gearbox Suppliers - conveyor drive assemble – Intech, The product will supply to all over the world, such as: Dubai, Slovak Republic, Rotterdam, Due to good quality and reasonable prices, our products have been exported to more than 10 countries and regions. We are looking forward to cooperating with all customers from at home and abroad. Moreover, customer satisfaction is our eternal pursuit.

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!