China Best Famous Perpendicular Speed Reducer Manufacturers - gear units for bucket elevators – Intech

China Best Famous Perpendicular Speed Reducer Manufacturers - gear units for bucket elevators – Intech Detail:

• Maximum power capacity

• Maximum operational reliability

• Fast availability

• Modular design principle

Technical data

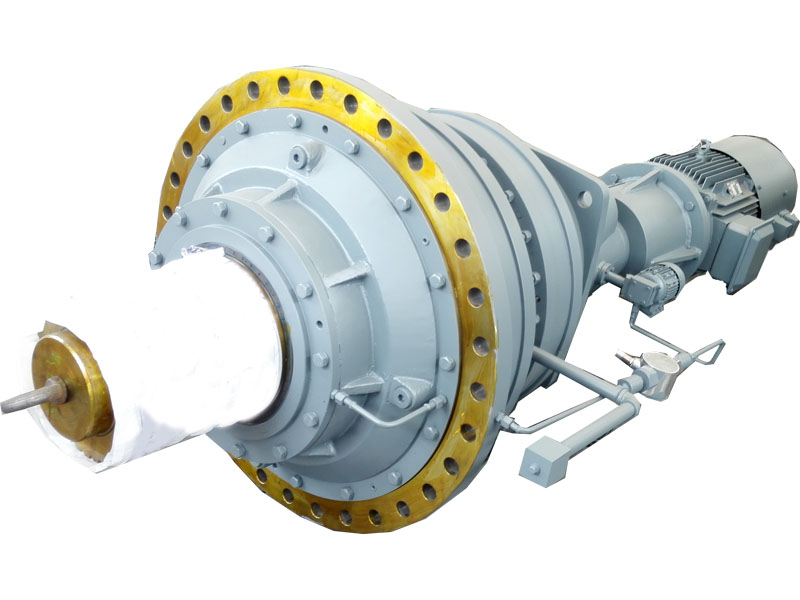

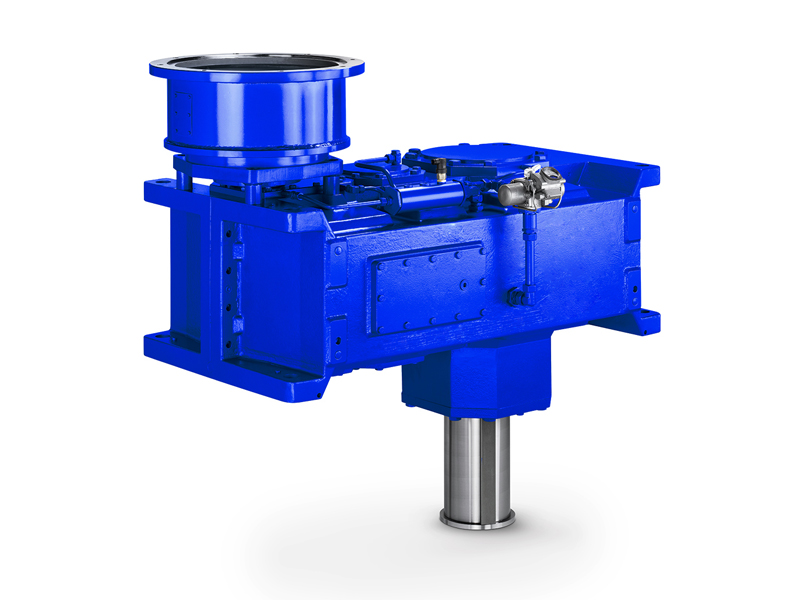

Types: Bevel helical gear unit

Sizes: 15 sizes from 04 to 18

No. of gear stages: 3

Power ratings: 10 to 1,850 kW (auxiliary drive power from 0.75 to 37 kW)

Transmission ratios: 25 – 71

Nominal torques: 6.7 to 240 kNm

Mounting positions: Horizontal

Reliable Gear Units for High Performance Vertical Conveyors

Bucket elevators serve to vertically transport large masses of bulk material to different heights without creating dust, then dump it. The height to be overcome is frequently more than 200 meters. The weights to be moved are enormous.

The carrying elements in bucket elevators are central or double chain strands, link chains, or belts to which the buckets are attached. The drive is located at the upper station. The features specified for the drives destined for these applications are similar to those for steeply ascending belt conveyors. Bucket elevators require a comparatively high input power. The drive must be soft-starting because of the high starting power, and this is achieved by means of fluid couplings in the drive train. Bevel helical gear units are normally used for this purpose as single or twin drives on a base frame or swing base.

They are characterized by maximum performance and operational reliability as well as optimal availability. Auxiliary drives (maintenance or load drives) and backstops are supplied as standard. The gear unit and the auxiliary drive are therefore perfectly matched.

Applications

Lime and cement industry

Powders

Fertilizers

Minerals etc.

Suitable for transporting hot material (up to 1000°C)

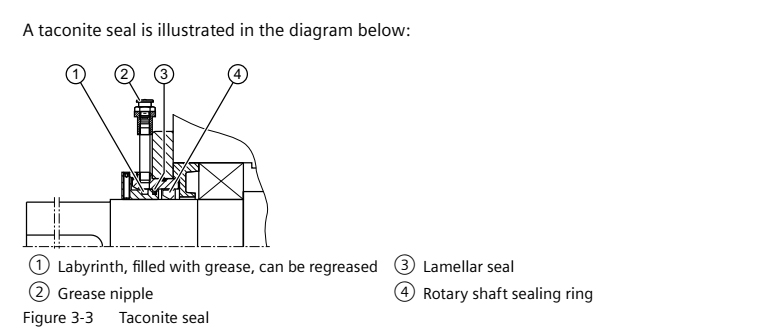

Taconite seal

The taconite seal is a combination of two sealing elements:

• Rotary shaft sealing ring to prevent the escape of lubricating oil

• Grease-filled dust seal (comprising a labyrinth and a lamellar seal) to allow operation of the

gear unit in extremely dusty environments

The taconite seal is ideal for use in dusty environments

Oil level monitoring system

Depending on the order specification, the gear unit can be equipped with an oil level monitoring system based on a level monitor, a level switch or a filling-level limit switch. The oil level monitoring system has been designed to check the oil level when the gear unit is at a standstill before it starts.

Axial load monitoring

Depending on the order specification, the gear unit can be equipped with an axial load monitoring system. The axial load from the worm shaft is monitored by a built-in load cell. Connect this to an evaluation unit provided by the customer.

Bearing monitoring (vibration monitoring)

Depending on the order specification, the gear unit can be equipped with vibration sensors,

sensors or with threads for connecting equipment for monitoring the rolling-contact bearings or gearing. You will find information about the bearing monitoring system design in the separate data sheet in the complete documentation for the gear unit.

Product detail pictures:

Related Product Guide:

Cooperation

Assume full accountability to fulfill all demands of our purchasers; attain continual advancements by marketing the advancement of our clientele; grow to be the final permanent cooperative partner of purchasers and maximize the interests of purchasers for China Best Famous Perpendicular Speed Reducer Manufacturers - gear units for bucket elevators – Intech, The product will supply to all over the world, such as: panama, Las Vegas, Czech Republic, Based on our automatic production line, steady material purchase channel and quick subcontract systems have been built in mainland China to meet customer's wider and higher requirement in recent years. We are looking forward to cooperating with more clients worldwide for common development and mutual benefit!Your trust and approval are the best reward for our efforts. Keeping honest, innovative and efficient, we sincerely expect that we can be business partners to create our brilliant future!

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!