China Best Famous Perpendicular Gear Reducer Factories - Planetary gear units for roller press – Intech

China Best Famous Perpendicular Gear Reducer Factories - Planetary gear units for roller press – Intech Detail:

Sizes:

P3DH345 P3DH370 P3DH395 P3DH420 P3DH445 P3DH475 P3DH500 P3DH525 P3DH545 P3DH575 P3DH595 P3DH620 P3DH635 P3DH665 P3DH700 P3DH740 P3DH775

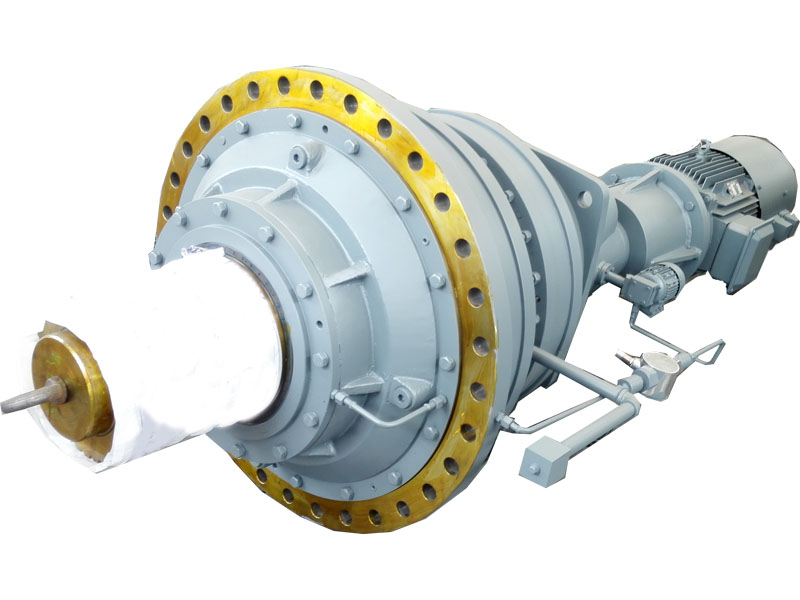

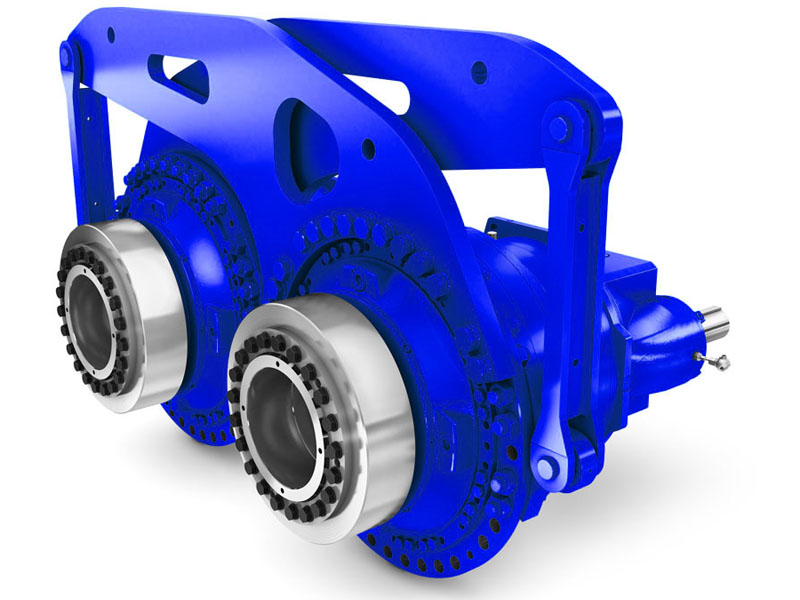

Compact design

• Up to 40% higher torque for the same installation dimensions compared to the normal roller press drive and competitors products

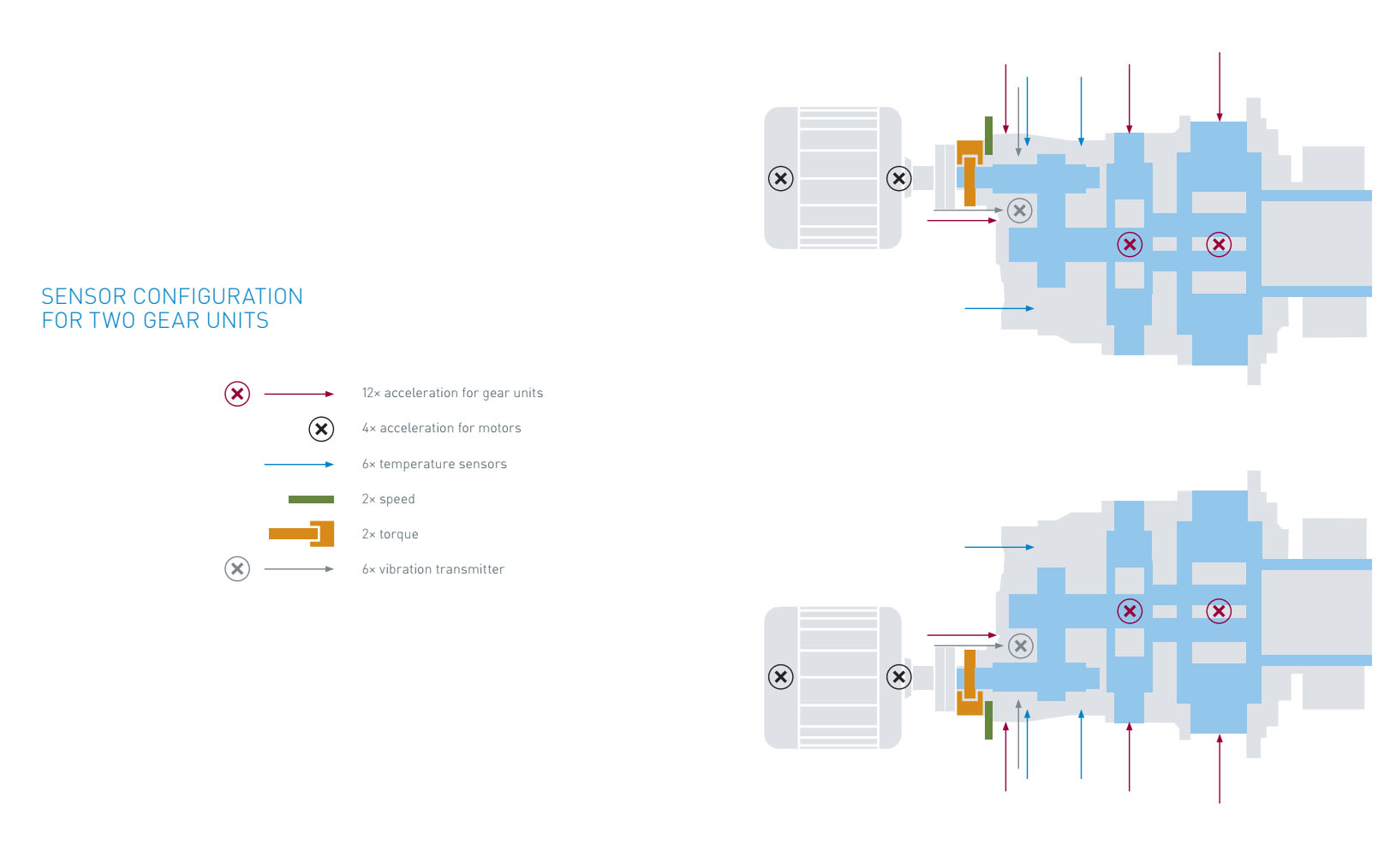

• Maximization of plant availability through optionally integrated measuring systems

• Low operating costs and high efficiency due to optimized gear geometries and the high level of manufacturing quality

• Precise adjustment of the output speed possible due to a stepless range of transmission ratios

• Shortest delivery times with a standardized roller press solution

• Smallest achievable roller distances thanks to top performance in a small installation space

• Long service life through application-oriented design and top-class quality

• High-performance input shaft bearings to absorb additional external forces emanating from the universal joint shaft and with an optional protective device for load-free rotation over a short period of time

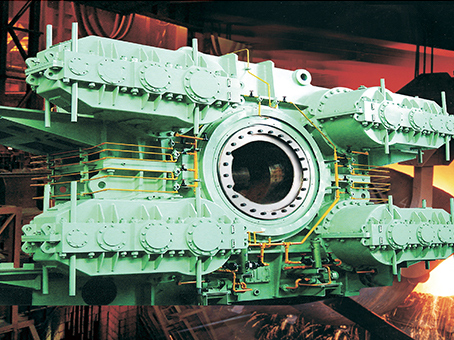

Extremely strong. Extremely compact. Extremely stressable.

Efficiency and reliability for rolling mills and roller presses

Uneven loads, extreme axial and radial forces, high dust generation – the grinding of iron ore, limestone and clinker is marked by harsh working conditions. High-pressure rolling mills and rotary kilns are particularly demanding applications that call for maximum performance and reliability from the drive systems. The grinding process must be guaranteed energy-efficient and reliable at the same time. The gear units are the perfect solution for rolling mills and roller presses. Their low weight reduces loads on gear units and machines. High radial and axial additional forces exerted by universal-joint shafts and floating-roller acceleration are absorbed by the standard bearing system. The high overload capacity here ensures operational reliability and stabilises your process.

Applications

• Cement industry

• Mines

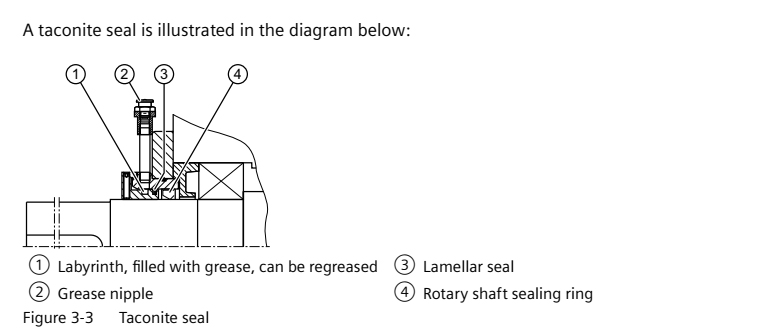

Taconite seal

The taconite seal is a combination of two sealing elements:

• Rotary shaft sealing ring to prevent the escape of lubricating oil

• Grease-filled dust seal (comprising a labyrinth and a lamellar seal) to allow operation of the

gear unit in extremely dusty environments

The taconite seal is ideal for use in dusty environments

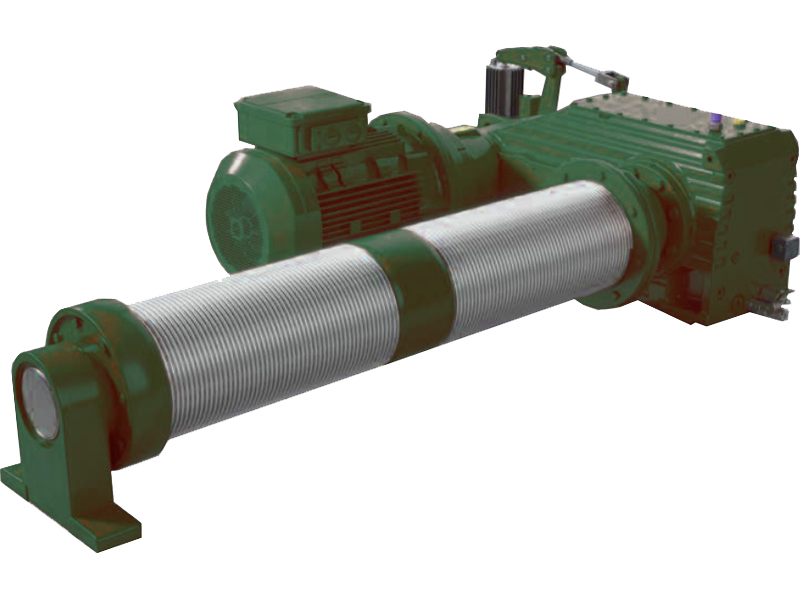

Oil level monitoring system

Depending on the order specification, the gear unit can be equipped with an oil level monitoring system based on a level monitor, a level switch or a filling-level limit switch. The oil level monitoring system has been designed to check the oil level when the gear unit is at a standstill before it starts.

Axial load monitoring

Depending on the order specification, the gear unit can be equipped with an axial load monitoring system. The axial load from the worm shaft is monitored by a built-in load cell. Connect this to an evaluation unit provided by the customer.

Bearing monitoring (vibration monitoring)

Depending on the order specification, the gear unit can be equipped with vibration sensors,

sensors or with threads for connecting equipment for monitoring the rolling-contact bearings or gearing. You will find information about the bearing monitoring system design in the separate data sheet in the complete documentation for the gear unit.

As an alternative, measuring nipples can be attached to the gear unit to prepare it for monitoring

Product detail pictures:

Related Product Guide:

Cooperation

To be a result of ours specialty and repair consciousness, our corporation has won an excellent reputation amongst customers all around the entire world for China Best Famous Perpendicular Gear Reducer Factories - Planetary gear units for roller press – Intech, The product will supply to all over the world, such as: Swedish, Wellington, Bhutan, Providing Quality Items, Excellent Service, Competitive Prices and Prompt Delivery. Our products and solutions are selling well both in domestic and foreign markets. Our company is trying to be one important suppliers in China.

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!