China Best Famous Gear Teeth Coupling Factories - wind power universal couplings – Intech

China Best Famous Gear Teeth Coupling Factories - wind power universal couplings – Intech Detail:

Product Parameters

|

Model |

101~130 |

|

Allowable rotational speed(r/min) |

500~4000 |

|

Nominal toyque(N.m) |

630~280000 |

Product Description

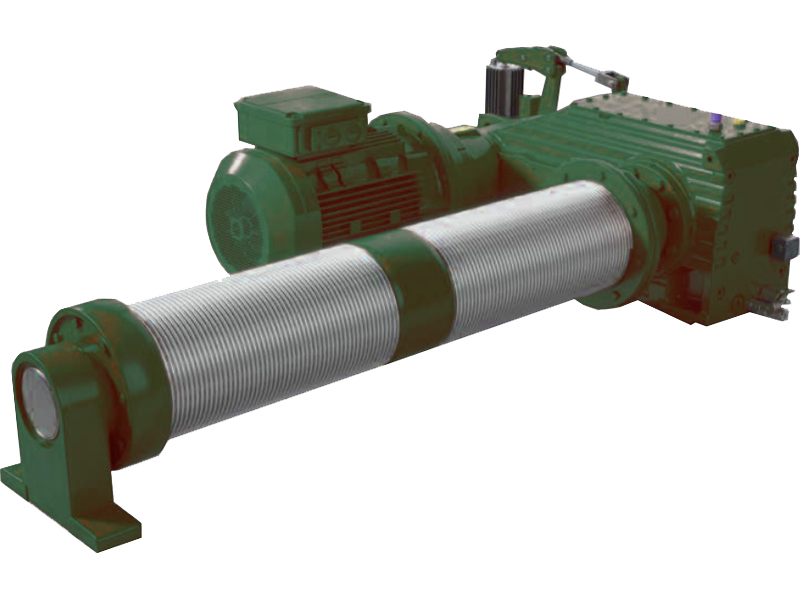

Wind power universal coupling

Wind power universal coupling has the advantage of compact, small moment of inertia, reliable work, carrying capacity and a small amount of compensation performance. Compared to the other types of coupling, it has the maximum torque transmission in same size. Widely used in metallurgy, mining, building materials, chemicals, petroleum, transport, textile and other industries.

Gear coupling, working environment temperature -20 to +80, nominal toque transfer for 0.4 to 4500kNm, allowable speed for the 4000 to 460r/min, shaft diameter range of 16 to 1000mm.

Wind power test station universal coupling

Wind power test universal coupling also name cardon coupling, the main feature is it can connecting two shafts located at not coaxial, and can drive it with high reliability in torque and rotation transmission. It has the advantage of compact, small moment of inertia, no noise, stable operation, long life, reliable work, carrying capacity and a big amount of compensation of angle. Compared to the other types of coupling, it has the maximum torque transmission in same size. Widely used in metallurgy, steel making, crane and transporting machine, mining, building materials, chemicals, petroleum, shipping, stage machine, wind power, textile and other industries.

Wind power test universal coupling has SWC(whole fork), SWP (split bearing support), SWZ (whole bearing support) types based on bearing fixed type.

Based on end plate fixed type, there are flange end with key, end teeth, teeth engagement, fast assembling and etc, the connecting method to driving or driven shaft has cylinder with key, cylinder without key, not circle hole and etc. The end flange diameter can be bigger than rotatory diameter.

Gear coupling, working environment temperature -20 to +80, nominal toque transfer for 0.4 to 45000kNm, allowable speed for the 4000 to 460r/min, shaft diameter range of 16 to 2000mm.

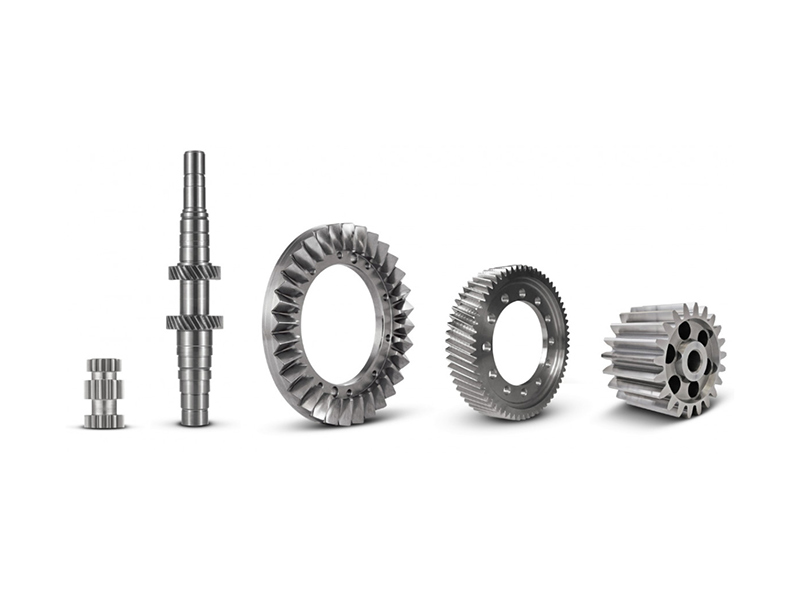

Product detail pictures:

Related Product Guide:

Cooperation

The incredibly rich projects administration experiences and a person to 1 service model make the substantial importance of organization communication and our easy understanding of your expectations for China Best Famous Gear Teeth Coupling Factories - wind power universal couplings – Intech, The product will supply to all over the world, such as: Qatar, Israel, Malaysia, Our company offers the full range from pre-sales to after-sales service, from product development to audit the use of maintenance, based on strong technical strength, superior product performance, reasonable prices and perfect service, we will continue to develop, to provide the high-quality products and services, and promote lasting cooperation with our customers, common development and create a better future.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.