cable reel reducer gearbox for collectors

- Motor (with drive)

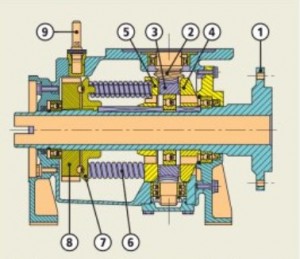

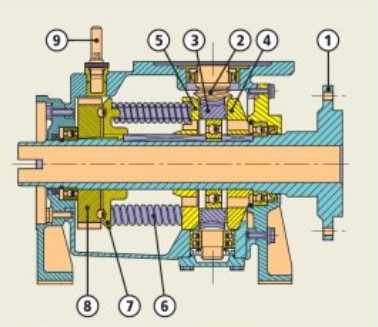

- Gearbox or torque unit

- Collector

- Drum

This system drive by hydrodynamic system, torque variable from 10-1200 daNm, Standard drum size vary from 300mm-8700mm diameter and more.

Hydrodynamic torque unit is the best alternative cable reel system to the traditional torque motor reels. It was the first system which used conventional squirrel cage electric motors.

The most unique feature of this hydrodynamic system is that its clutch is acting directly on the main drum shaft.

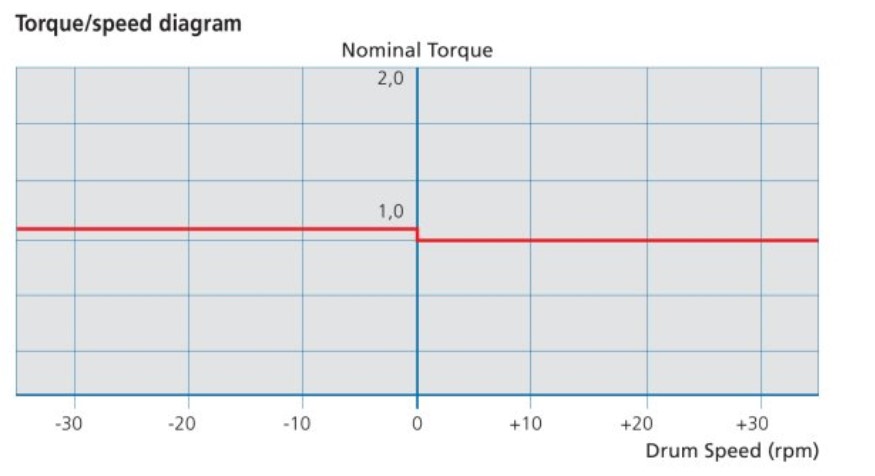

This gives an even torque output in reeling and unreeling modes, independently of clutch slip or reeling speed, thus assuring a long life for the cable.

The diagram shows the typical torque/speed diagram for a hydrodynamic torque unit with an unbeaten even torque output. The torque variation due to slip or reeling speed does not exceed 5-10% depending on the torque unit size.

Duce to its unique patented design, the hydrodynamic system provides a simple and rational solution for many cable and hose reel applications. The system is based on a gearbox in which a reduction gear, clutch and brake are built as one unit. It provides a constant torque output, allowing an even recovery of any type of cable.

This is similar Cavotec Specimas hydrodynamic cable reel is driven by a standard squirrel cage motor but can also be supplied with a hydraulic or pneumatic motor. Another major advantages is that the torque can easily be readjusted on site.

This way, the tension of the cable may be reduced or increased according to actual requirements.

Hydrodynamic cable reels are at work throughout the world on harbor cranes, container cranes, mining machines and mobile cranes.

Gears are caburizing quenching harden gear with long life with surface hardness of HRC58-62, and precision of DIN6 to realize low noise, high reliability.

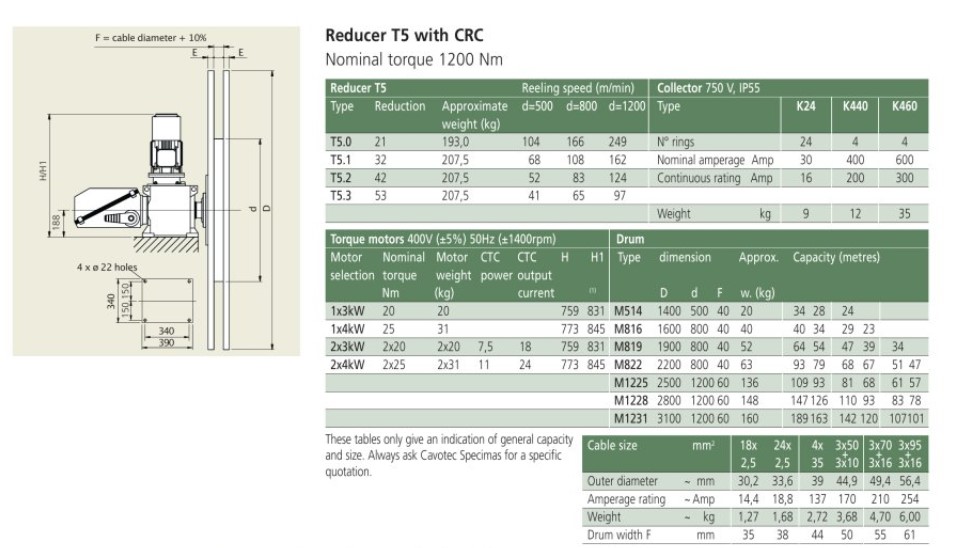

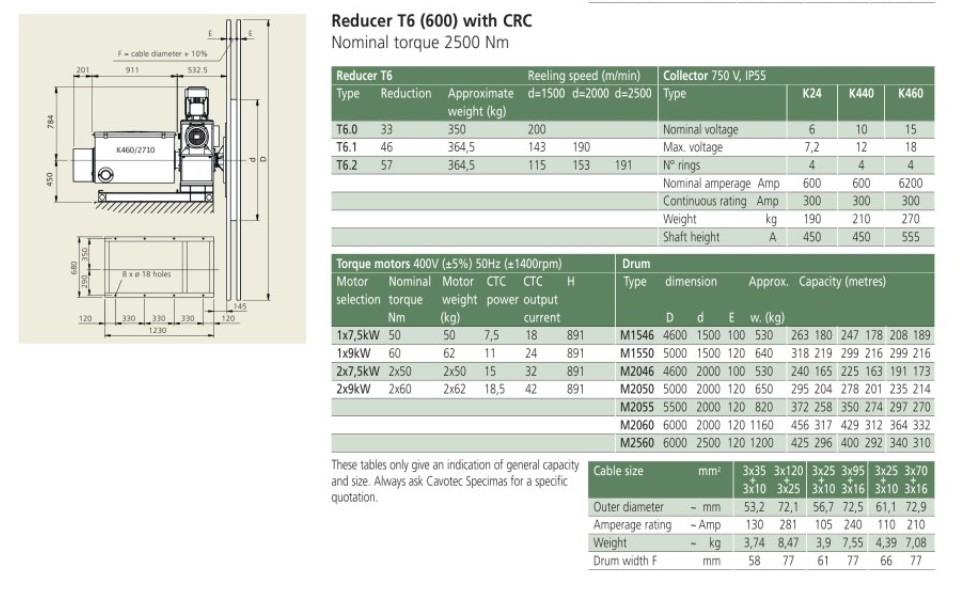

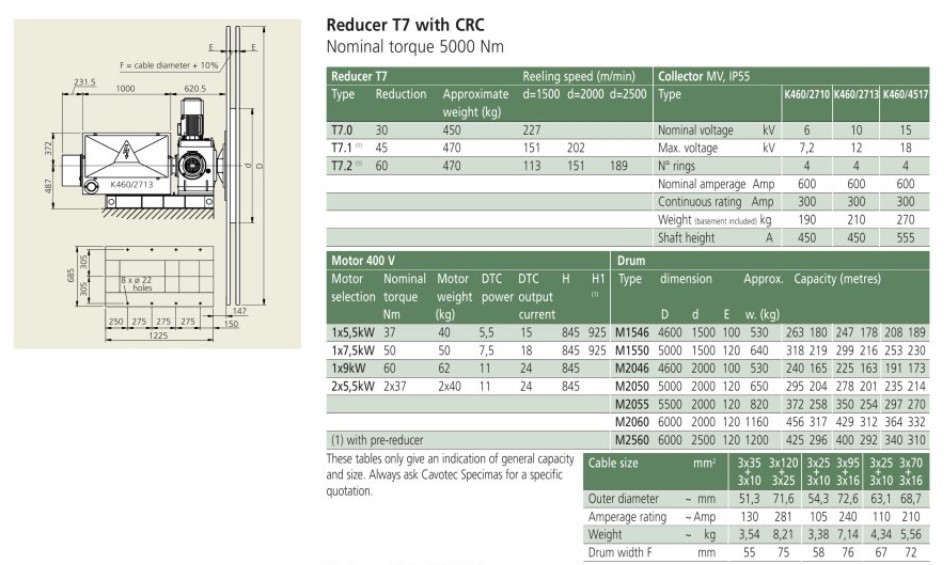

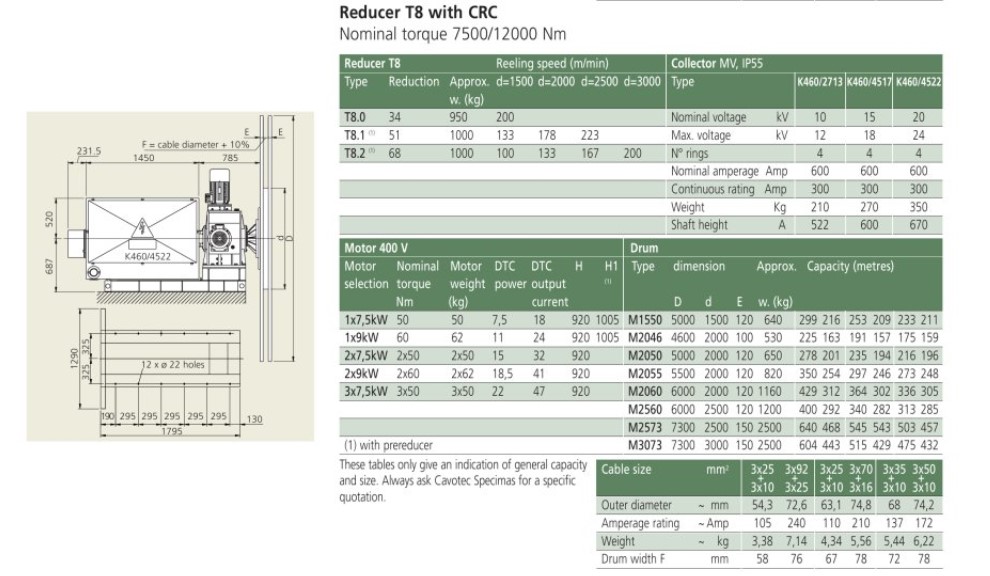

| Reducer T5 with CRCReducer T6 T600 with CRCReducer T7 with CRCReducer T8 with CRC |